Want to buy a tube laser cutting machine? Knowing the price is key. Learn about factors that affect prices. Be informed to make smart choices for your business.

How much does a tube laser cutting machine cost?

In 2024, the global market for laser tube cutting machines has become quite mature. Equipment prices are also stabilizing. Nowdays, the price of a tube laser cutting machine ranges from US $30,000 to $400,000. And the average transaction price is around US $60,000.

Prices of different levels of tube laser cutting machines:

We made it easier to understand laser tube cutting machine prices by dividing them into three levels: entry-level, mainstream configuration, and flagship. This helps you compare prices more easily.

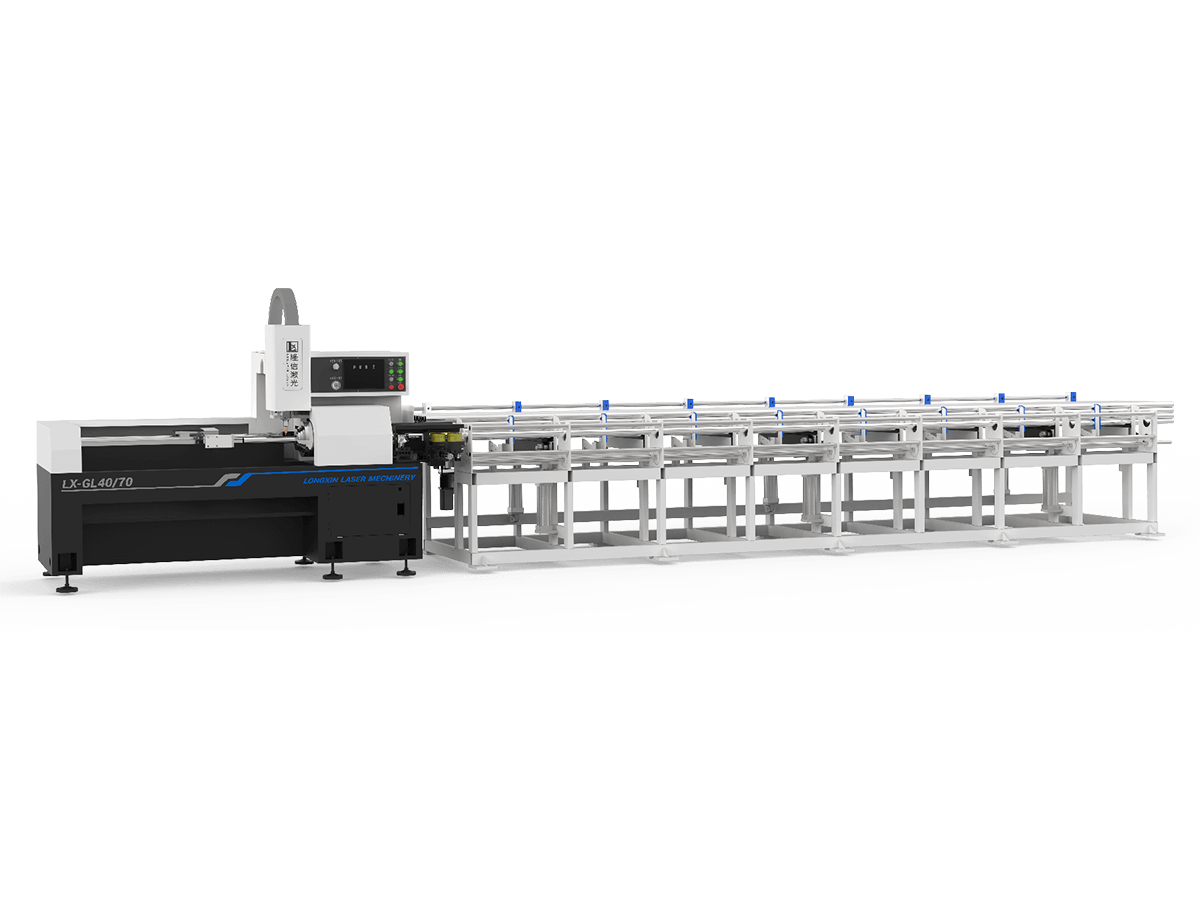

1.Entry-Level tube laser cutting machine price

Entry-level tube laser cutters are basic machines that can cut round tubes and rectangular tubes with cutting precision. They do not have advanced features like drilling or bevel cutting. Mostly, the tube feeding process remains semi-automatic, although there is an option for fully automatic loading which comes at a higher cost.

The price of entry-level tube laser cutting machine cost US $30,000 to $45,000.

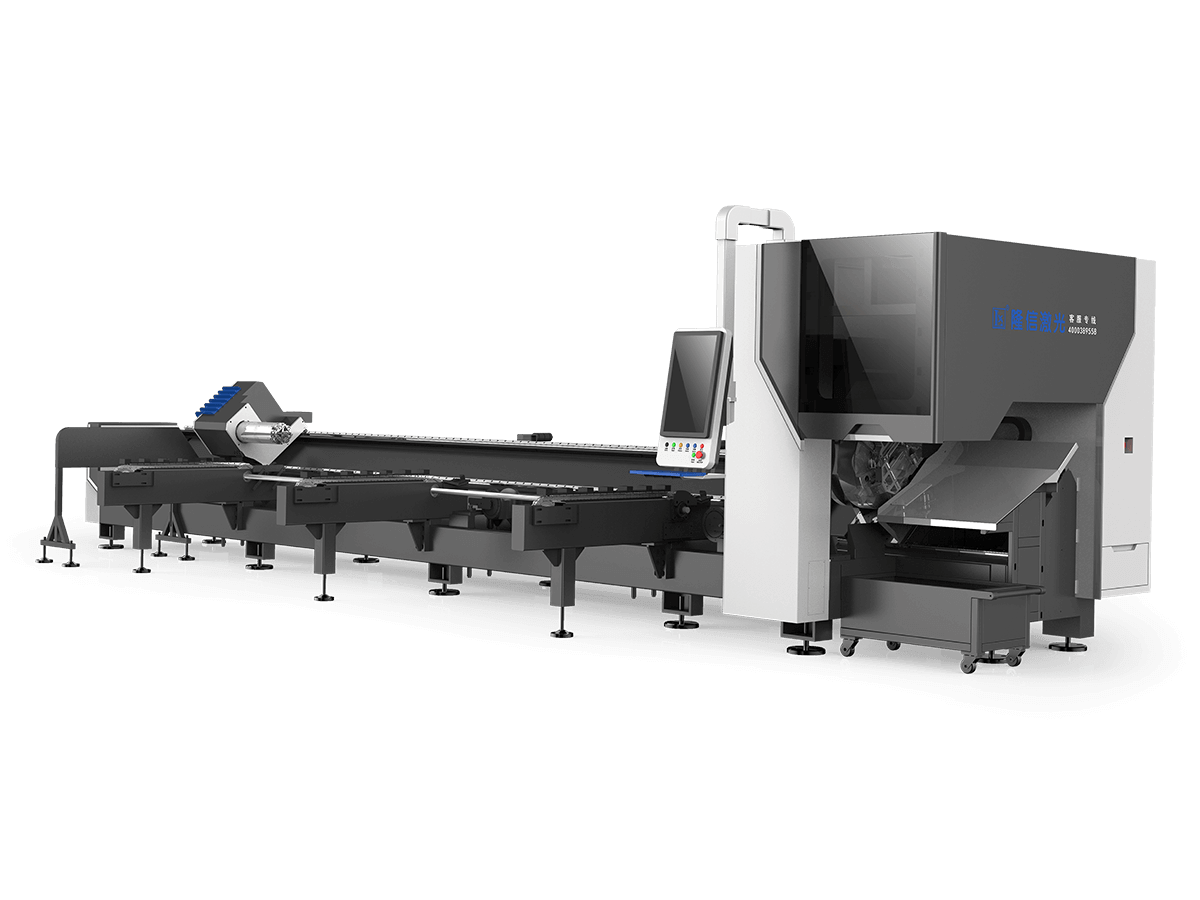

2.Mainstream configuration tube laser cutting machine price

A mainstream configuration laser cutting machine for tubes typically comes with a comprehensive setup to cater to various tube processing requirements.

Apart from the fundamental tube cutting function, this type of machine also facilitates intricate processes like drilling, milling, sawing, stamping, and burr cleaning. It is capable of cutting special-shaped pipes such as oval tubes, profiles, channel steel, and angle steel.

Given the extensive functionality and customization options available in mainstream laser tube cutting machines, the selection of different components can result in vastly different final pricing.

Consequently, the price range for a mainstream configuration tube laser cutting machine usually falls between US $45,000 to $100,000.

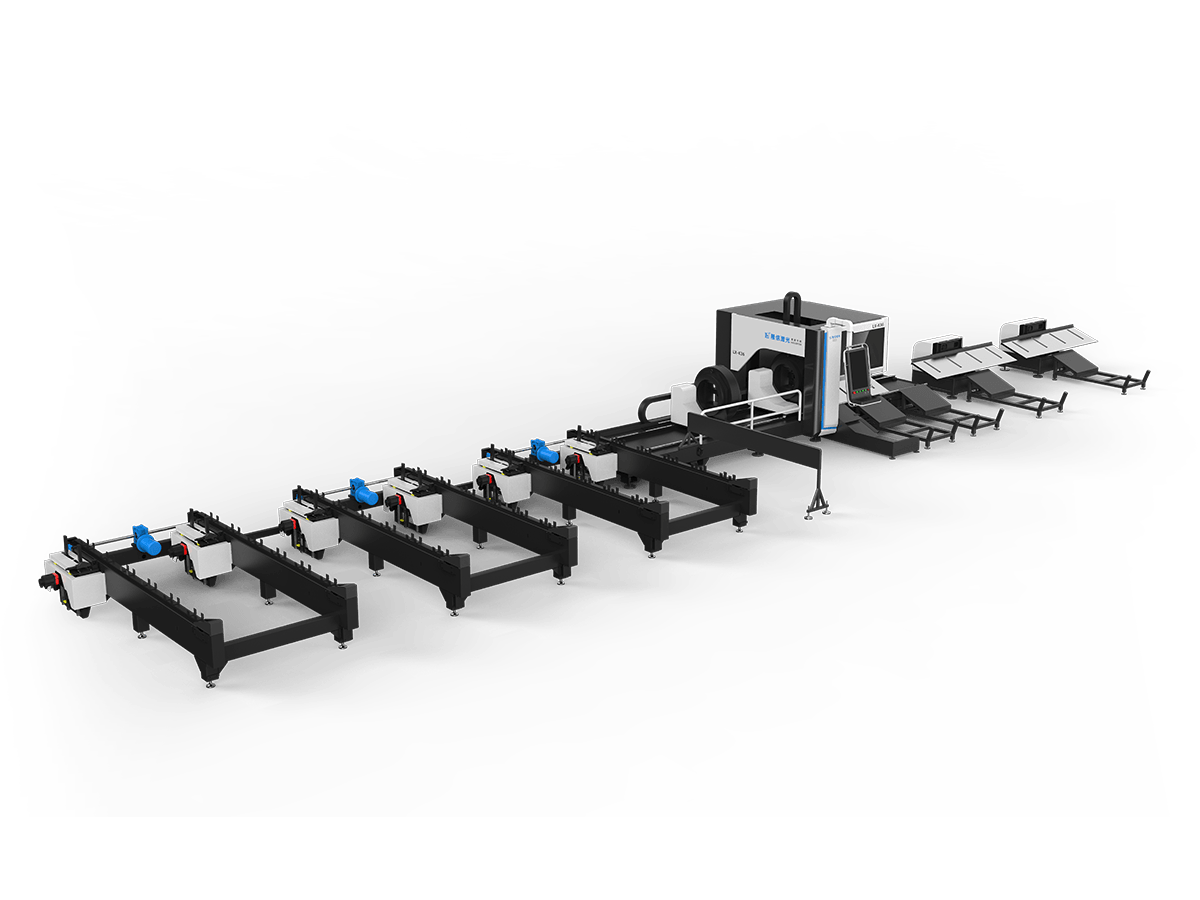

3.Flagship grade tube laser cutting machine price

The flagship laser cutting systems embody the highest level of manufacturing prowess for each brand. This premium tier of equipment is deeply customized with a laser head to meet the specialized tube cutting needs of certain customers. It caters to clients with exceptionally stringent expectations around cutting quality or productivity.

The flagship models not only offer all the standard functionality and dimensions, but also integrate the latest cutting-edge technologies.

Examples include combined threading and tube bending functionality, the option for extra-long (over 40 meter) feed racks, the handling of tube diameters greater than 360mm, single-tube weight support over 500kg, and 45-degree bevel cutting, etc.

Naturally, the sophisticated configurations and advanced capabilities of these premium-grade systems come at a commensurate cost.

As a result, the flagship laser tube cutting machines are usually listed at over US $100,000. In fact, final selling prices between US $200,000 to $400,000 are relatively commonplace.

Cost factors of tube laser cutting machine

1.Functional Configuration

Before determining the price of the laser tube cutting machine you require, you need to first clearly define your own processing needs. Based on this, you can then identify the necessary machine configuration.

The more features and capabilities the equipment possesses, the higher the price. If you have demanding production requirements, such as high-speed cutting or the ability to process large and heavy-duty tubes, the equipment cost will be commensurately greater.

2.Production Capacity

The machine’s productivity is a crucial factor influencing the price. Laser tube cutting equipment can be semi-automatic or fully automatic, and the level of automation directly determines the system’s output capacity.

For instance, machine capabilities such as automated material loading/unloading and cutting head exchange enable higher work efficiency and throughput, which consequently impact the overall pricing.

3.Critical Parts

The essential components of a laser tube cutting machine comprise the fiber laser source, laser tube, laser optics, cutting head, control system, and servo motors. These core parts determine the maximum quality potential of the laser cutting equipment.

The prices of these main parts can vary a lot between brands. For example: the purchase price of international laser giant IPG will be much higher than that of Raycus and MAX from China. But there won’t be a big difference in actual performance. And these costs affect how much the equipment will cost in the end.

4.Power Rating

For any given laser equipment model, higher power ratings correlate with higher pricing. This is a well-established principle in the laser cutting domain.

As such, prior to seeking quotes from suppliers, buyers must clearly define the material types and thicknesses they need to process, as well as their required cutting speeds and production throughputs. This ensures they avoid over-specifying and making unnecessary investments.

5.Brand Premium

Well-known brands in the laser tube cutting machine market are highly valued by customers because of their good reputation, long history, cool designs, and expert manufacturing skills. This makes them able to charge higher prices.

These brands have built their standing on superior product quality and service, and for some prospective buyers of laser tube cutting equipment, selecting a prominent brand represents a low-risk proposition.

However, laser tube cutting machines are generally highly customized, and even esteemed brands cannot ensure flawless performance of every individual unit. Therefore, buyers should not become overly fixated on brands and blindly accept inflated premiums.

6.Supplier Services

Service is another crucial factor affecting pricing. Comprehensive after-sales support and technical assistance are typically reflected in the equipment cost.

When buying a laser tube cutting machine, you need to consider transportation, installation, training, consultation, and maintenance. Manufacturers offer different prices for these services.

For instance, domestic suppliers will generally offer more affordable service pricing compared to overseas providers.

Consequently, when assessing the pricing of laser tube cutting machines, it is important to factor in the associated service costs as well.

Conclusion

The discourse around laser tube cutting machine pricing is an ever-evolving topic. This blog post reflects the 2024 market conditions, but the specific equipment costs will continue to fluctuate in response to supply and demand trends.

If you aim to stay abreast of the latest price changes, we recommend that you keep track of Longxin laser’s latest news and information, or directly contact us to receive the most current quotations.