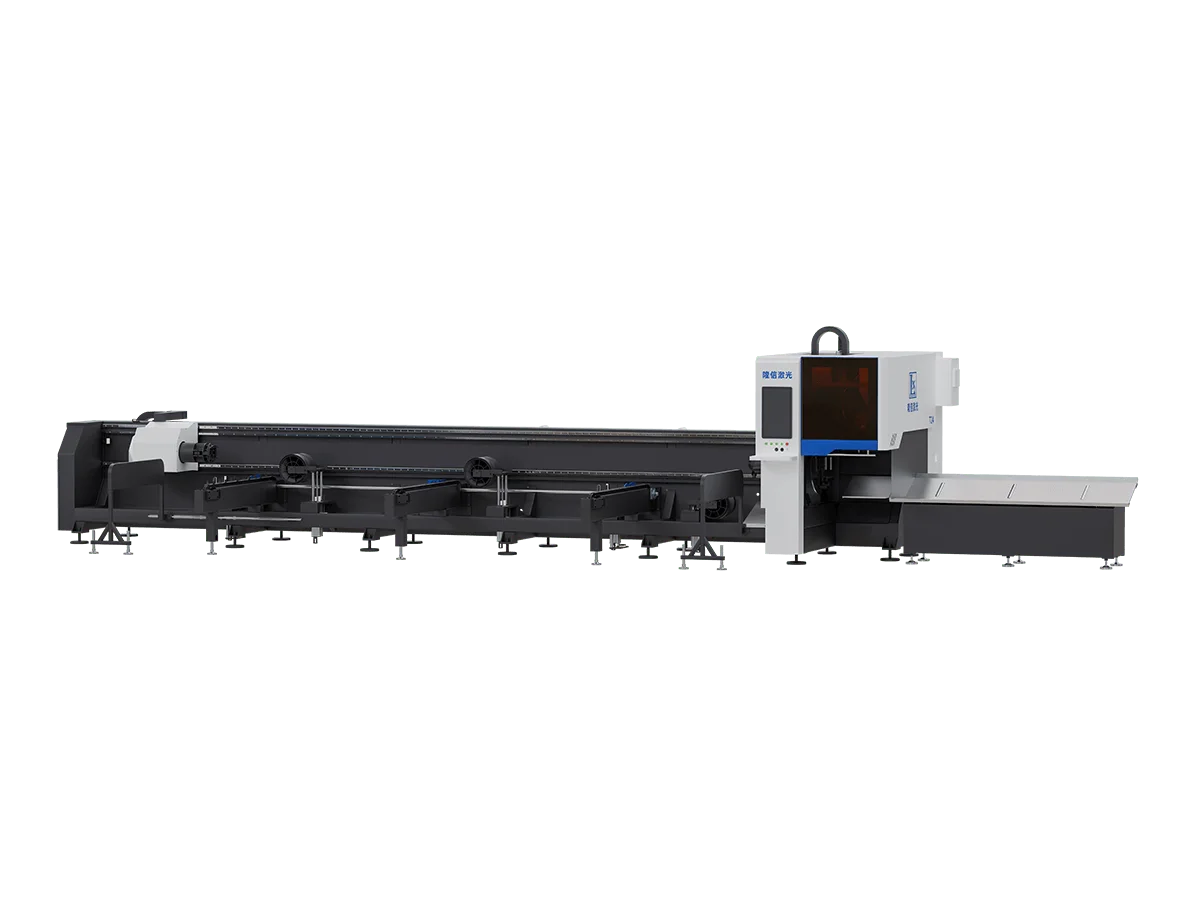

High speed laser tube cutting machine

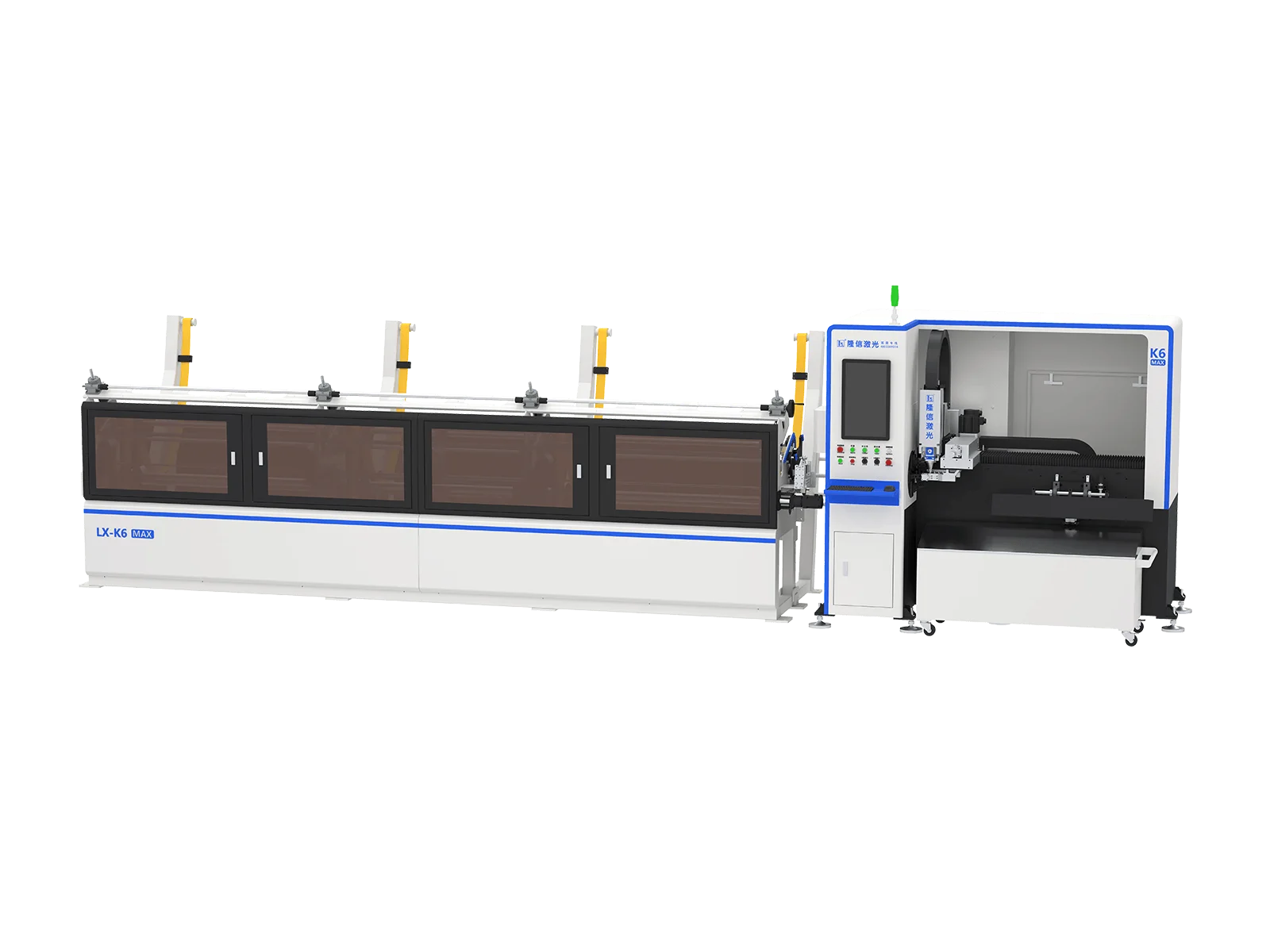

LX-K6MAX

- Customer-centric, combined with customer needs, fully independent research and development of hardware and software, mastering core technologies

- High-strength bed, fast speed, good stability

- Short tail material: ≥40mm

- Strong scalability, support for personalized customization

- High cost-effectiveness, fully automatic production

Reliable Quality with International Certifications

Our certificates that demonstrate the quality, reliability, and compliance of our products with international standards.

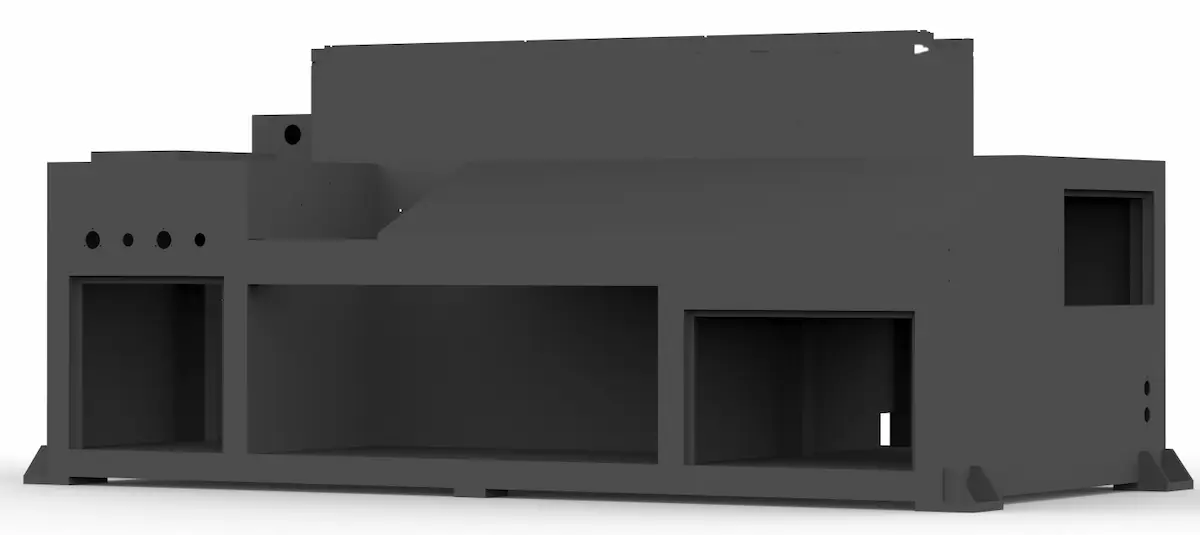

High strength structure

Adopting high-quality steel welded frame seal plate structure, after professional welding, high-temperature annealing, secondary aging treatment, large-scale gantry milling machine precision machining, to ensure that the machine tool has excellent shock resistance, high rigidity and stability.

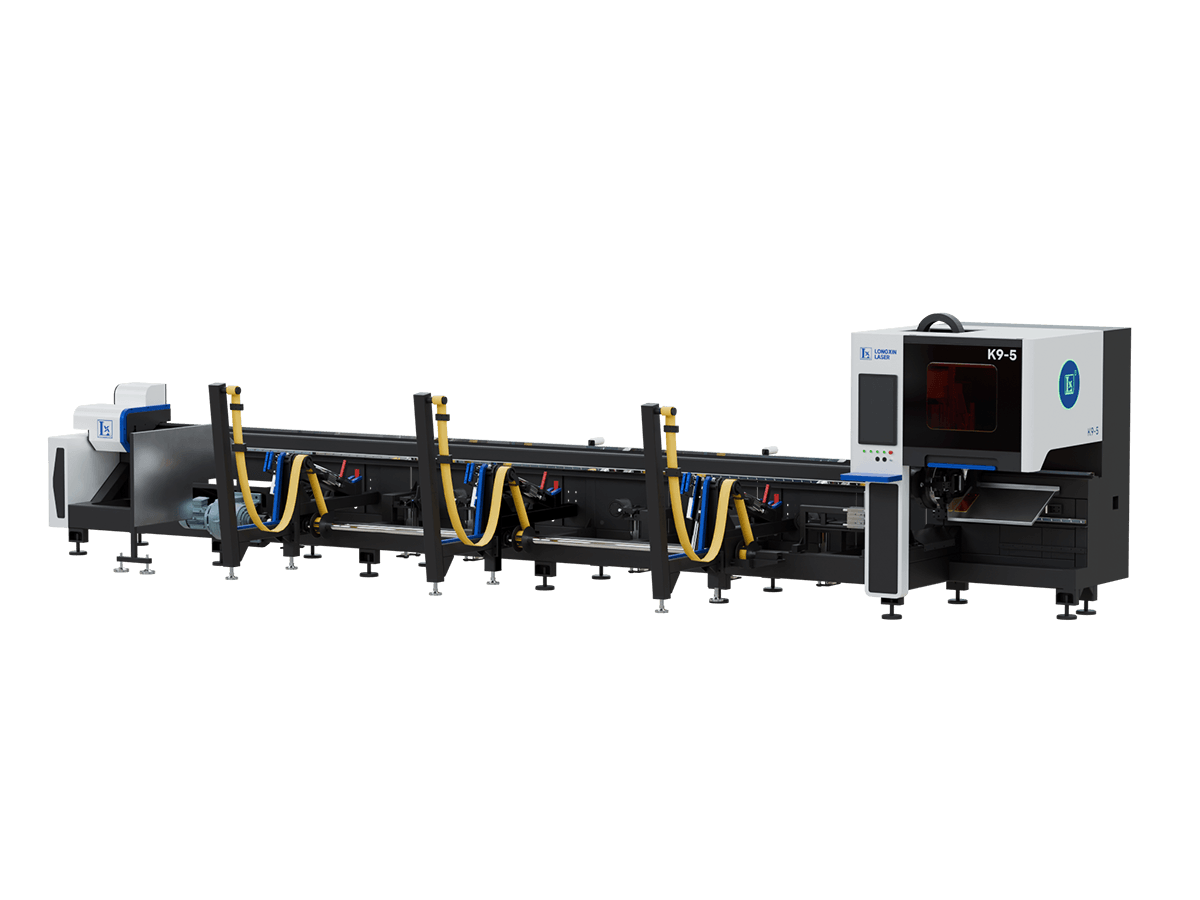

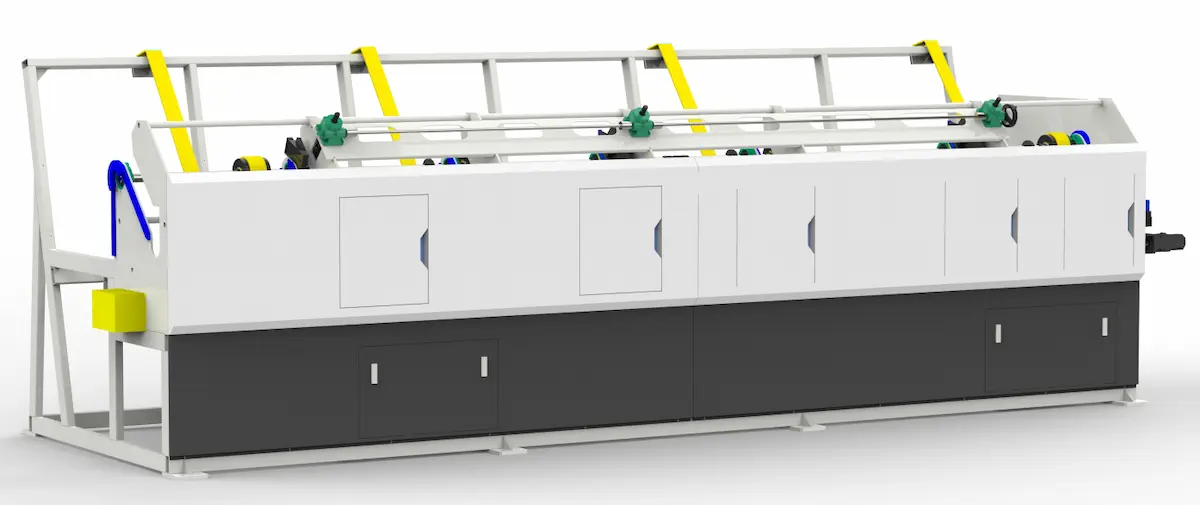

Self-developed automatic loading system

The maximum loading size is 89mm, except for customised size (external circle size), and the maximum weight of a single pipe is 35kg.

When loading tubes, only need to lift the material into the storage tank, the equipment can automatically complete the loading and cutting action.

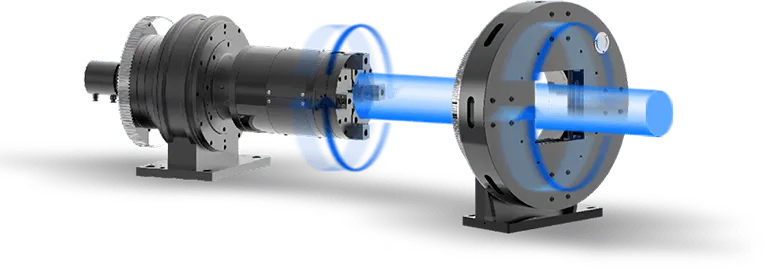

High precision one-piece universal chuck

This chuck is a universal chuck, easy to change type, and the shortest cutting waste can be controlled at 40mm.

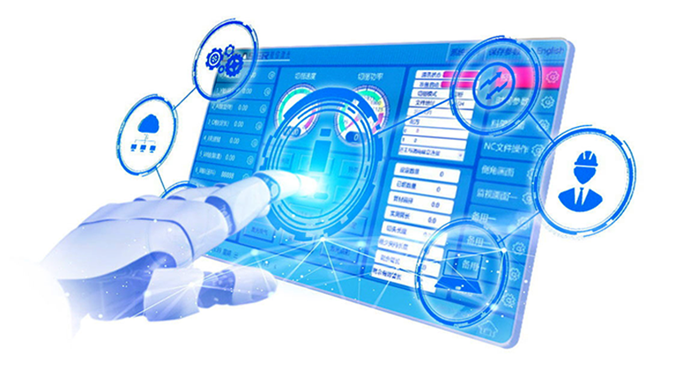

Self-Developed CNC Control System

LX-proprietary Controller ensures ease of use. No prior experience required, and proficiency in cutting is achieved with minimal training.

Technical Specifications

- Model

- Laser power

- Acceleration

- Dimensions round sections (min. – max.)

- Dimensions rectangular sections (min. – max.)

- Cutting tube length

- Dimensions (L*W*H)

- Machine weight

- Tube sections

Configuration List

- Fiber Laser

- Fiber Laser Cutting Head

- Control System

- Pneumatic Chuck

- Ball Screw

- Guide Rail

- Servo Motor and Driver

- Reducer

- Pneumatic Component

- Relay

- Machine Tool Accessories

- Machine Bed Frame

- Chiller

- Voltage Stabilizer

- Feeding Machine

Cutting Samples

Client Case

Customer Case: Karacabey Türkiye- Model: LX-K12MAX / LX-GL40 – Automotive Parts

Longxin Laser Model T24 Delivery and Global Smart Manufacturing Summit Successfully Concluded!

Longxin Thailand customer agent

Ultra-Large Diameter Round/Square Welded Pipe Online Intelligent Laser Cutting Machine

Steel Structure Industry Customer Case Studies

Longxin Laser’s Successful Customer Case:Indonesian Automobile Parts Manufacturing Factory.

Get a solution from Longxin

Just fill in form to get the free quotes and our all specifications.It takes less than a minute and is 100% free. No obligation to buy. Get it now!