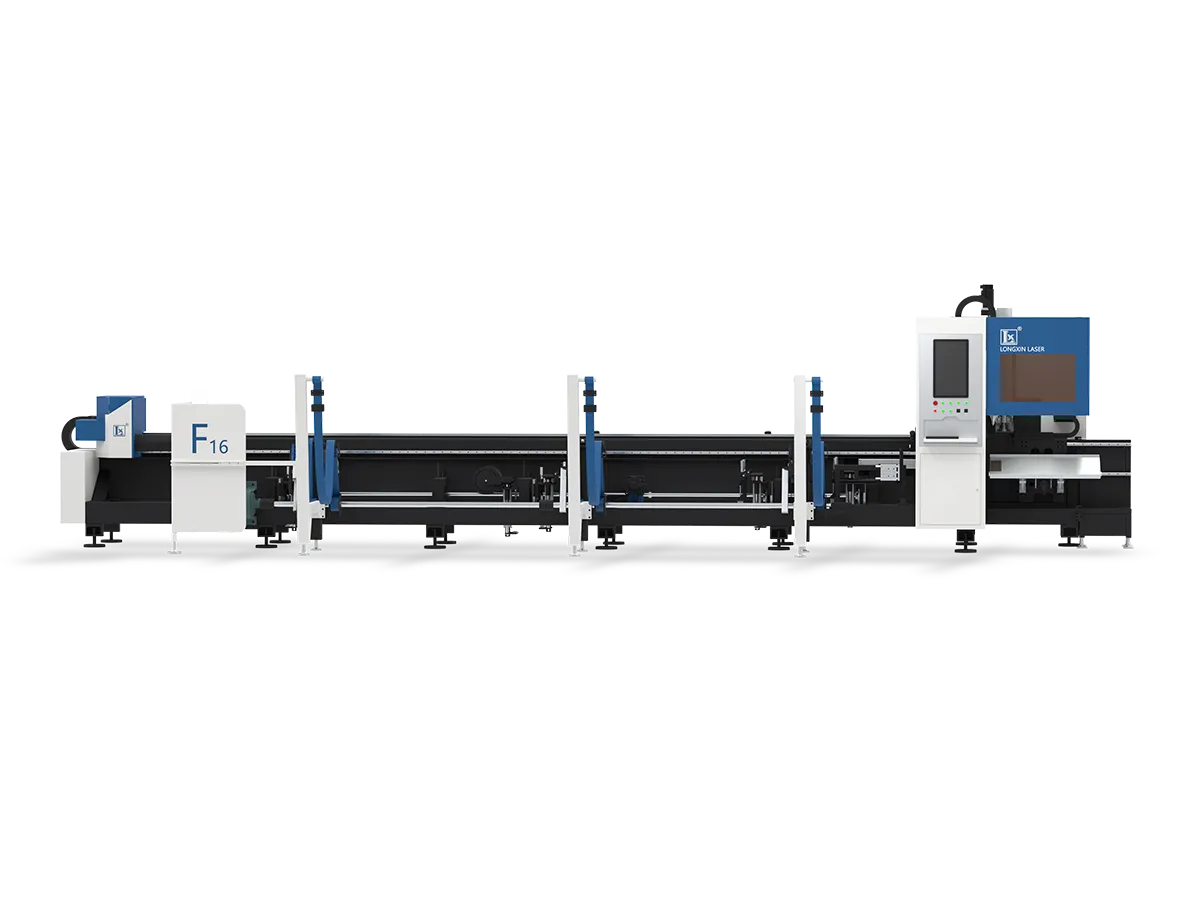

Multifunctional Pipe laser cutting machine

LX-F16

Inquiry now

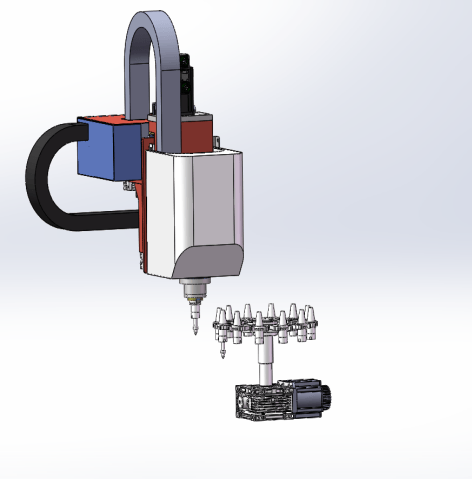

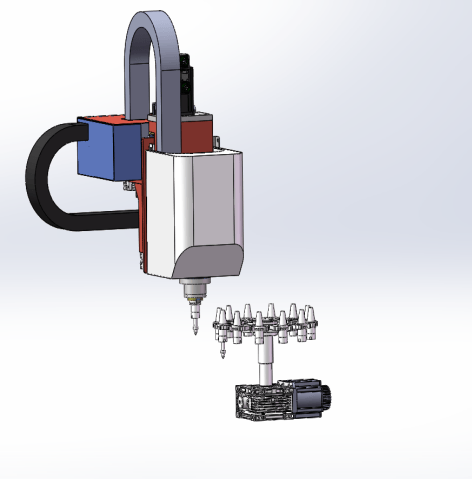

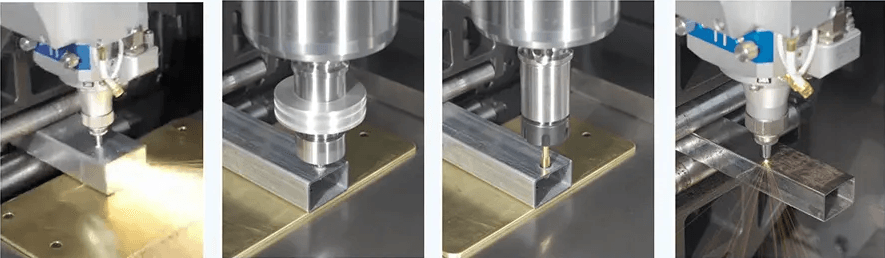

Multi-diameter thermal fusion drilling and tapping technology

Thermal drilling is a high-speed process using a specialized tungsten carbide tool. It generates temperatures of 650-750°C through friction, softening the metal locally. As the drill penetrates, it forms a bushing 3-4 times thicker than the original material in just 2-6 seconds. This bushing can be used for threading, strengthening connections, or creating supports and branches, making it an efficient technique for producing strong, functional holes in thin-walled materials without material removal.

Four-in-one functionality

A single tube processing machine integrates cutting, thermal drilling, tapping, and marking operations. This all-in-one processing approach reduces steps, minimizes labor, significantly shortens processing time, and enhances production efficiency.

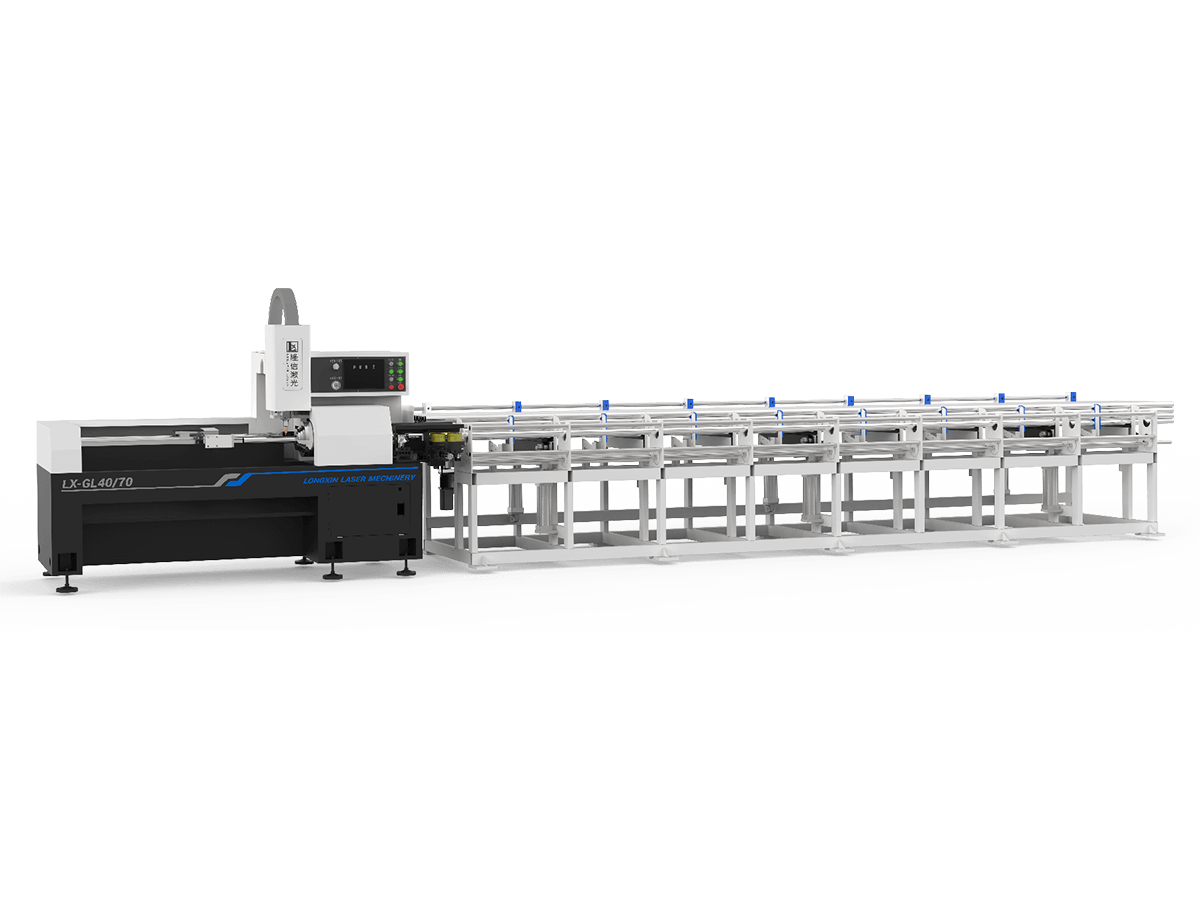

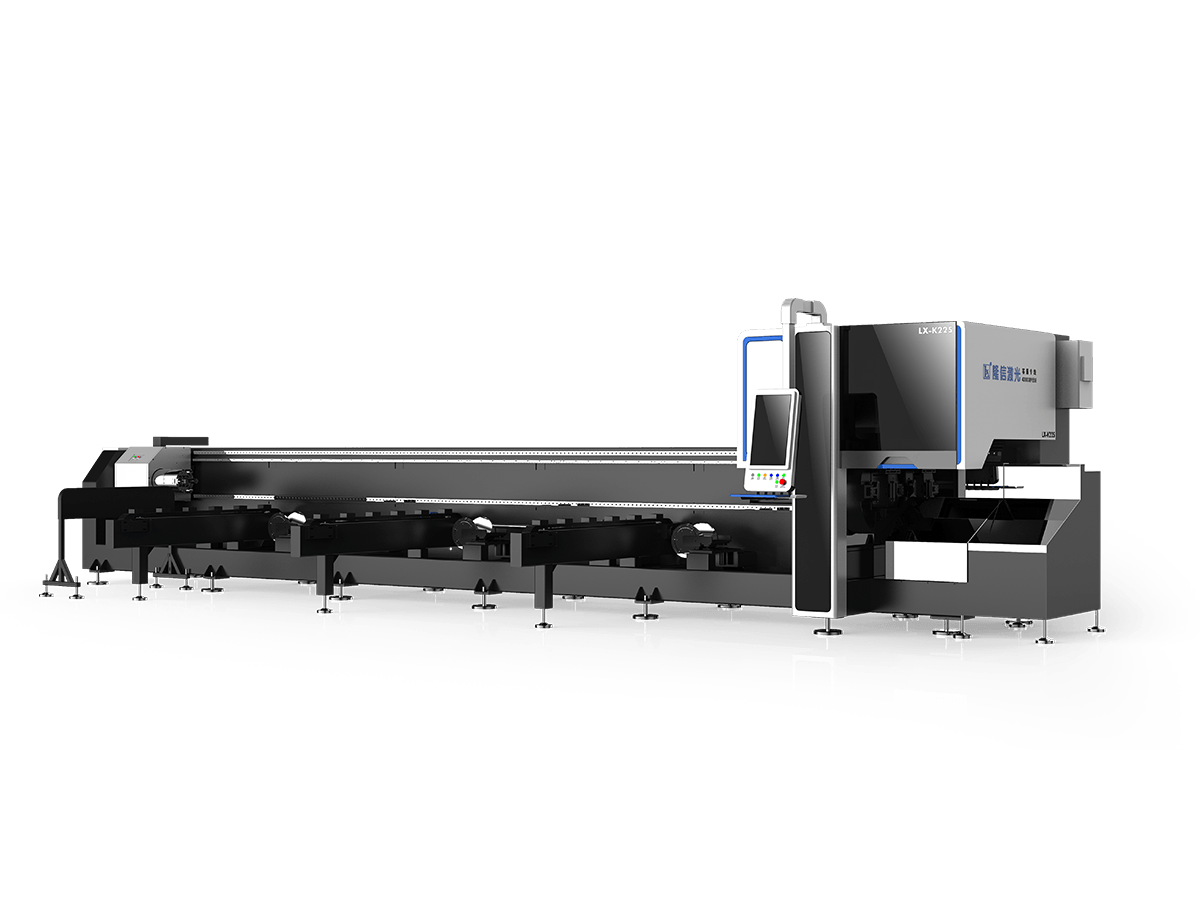

Flexible Configuration Options

Optional pneumatic or servo-driven loading and unloading systems. Choice of fully automatic or semi-automatic feeding mechanisms available.

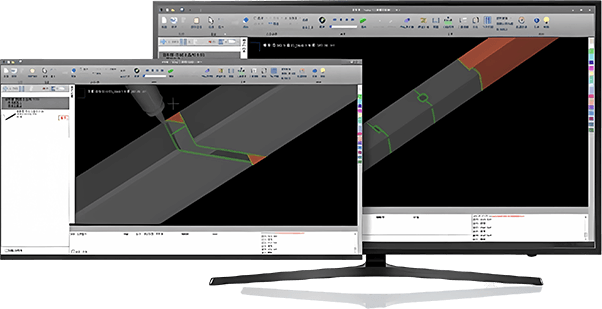

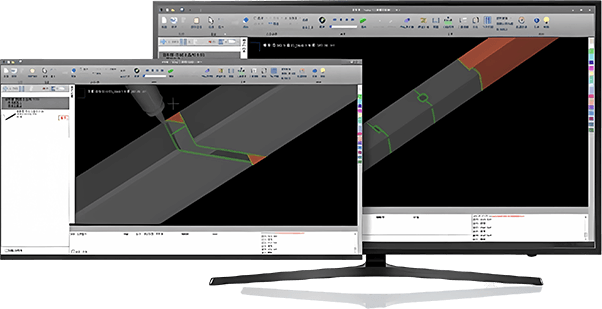

Advanced Customized Control System

The system is developed based on Windows and is compatible with EtherCAT bus technology, offering high reliability, superior performance, intelligence, and network integration. It features high cutting precision, fast cutting speed, minimal waste, and high efficiency

- Model

- Laser power

- Acceleration

- Dimensions round sections (min. – max.)

- Dimensions rectangular sections (min. – max.)

- Cutting tube length

- Dimensions (L*W*H)

- Machine weight

- Tube sections

Cutting Samples

Client Case

Optimizing Door and Window Frame Production: LX-K9 Application in Malaysian Manufacturing

LX-K9 Applications in Turkish Ladder Manufacturing

K6S Application in Vietnamese Furniture Manufacturing

Customer Case in China

LX-T12 Laser Tube Cutting Machine Enhances Outdoor Equipment Manufacturing in Vietnam

Transforming Aluminum with the LX-K9 Laser Tube Cutting Machine in Vietnam

Get a solution from Longxin

Just fill in form to get the free quotes and our all specifications.It takes less than a minute and is 100% free. No obligation to buy. Get it now!