Overview

Are you looking for information and comparisons on top 10 laser tube cutting machine manufacturers?

Lots of companies are bringing out new laser tube cutting machines. We put together a list of the best 10 global makers for 2024 to help people pick the right brand. These makers are really good at smart manufacturing.

We didn’t rank the companies because everyone has different needs for tube cutting, laser pipe cutter, and money. Each company has its own cool stuff based on what they’re good at.

Get ready for a journey into new ideas, precision, and super cool technology. Let’s dive into the world where laser beams shape the future.

1. Trumpf

About the company:

Head Quarter: United States

Established:1923

TRUMPF is a leading company in making laser tube cutting machines. They are known for being accurate and creative. Established in 1923, TRUMPF has grown from small workshops to a powerhouse in manufacturing, shaping the future of industry.

With 18,352 dedicated employees and a global footprint spanning 70 sales subsidiaries that stretch across continents, from the busy markets of Asia to the innovation centers of Europe and the Americas, TRUMPF certainly commands a strong presence as a manufacturing company.

TRUMPF is a big company that makes machine tools, lasers, and electronics. They have over 70 branches worldwide, with factories in countries like Germany, France, and China.

Related products:

The Trumpf TruLaser Tube 5000 fiber is a cool laser tube cutting machine. It uses a strong laser to cut different tubes and pipes fast and well. The machine can fit different tube shapes easily with its special clamping system. It can also cut at a 45-degree angle and tap pipes at the same time.

2. BLM GROUP

About the company:

Head Quarter: Italy

Established:1950

Let us focus on BLM Group- a symphony of innovation, accuracy, and Italian mastery that is heard down the metallic halls of the industry. BLM Group is an indelible mark in steel and fiber optics manufacturing and is known for high-quality laser cutting, tube bending, and CNC sawing machinery.

Being equipped with a palette of technologies, BLM Group is a one-stop shop phenomenon for metal processing lovers and manufacturing laser devices.

The Group is composed of three powerful entities which are BLM S.P.A., ADIGE S.P.A. and ADIGE-SYS S.P.A. and it provides a wide range of knowledge. Their machines hum the hum of technical superiority whether it is bending, cutting, or end-forming pipes, tubes, or products.

Related products:

BLM has 2D and 3D laser tube cutting systems for tubes, rods, and profiles in diameters from 12 mm to 610 mm (0.5” to 24”) and lengths up to 18 m (60’). BLM offers a wide range of pipe cutting solutions:

LT5.10 2D laser tube cutting machine, which is suitable for initial business in pipe processing.

LT7 is a fully automatic laser tube cutting machine that integrates thread tapping technology and cutting of bent pipes.

LT12 allows for tube and pipe processing with diameters of up to 305 mm. It is capable of handling tubes, pipes, and profiles weighing up to 62 kg per minute.

BLM utilizes its self-developed BLMelements nesting software, which is dedicated to reducing non-productive downtime and eliminating waste.

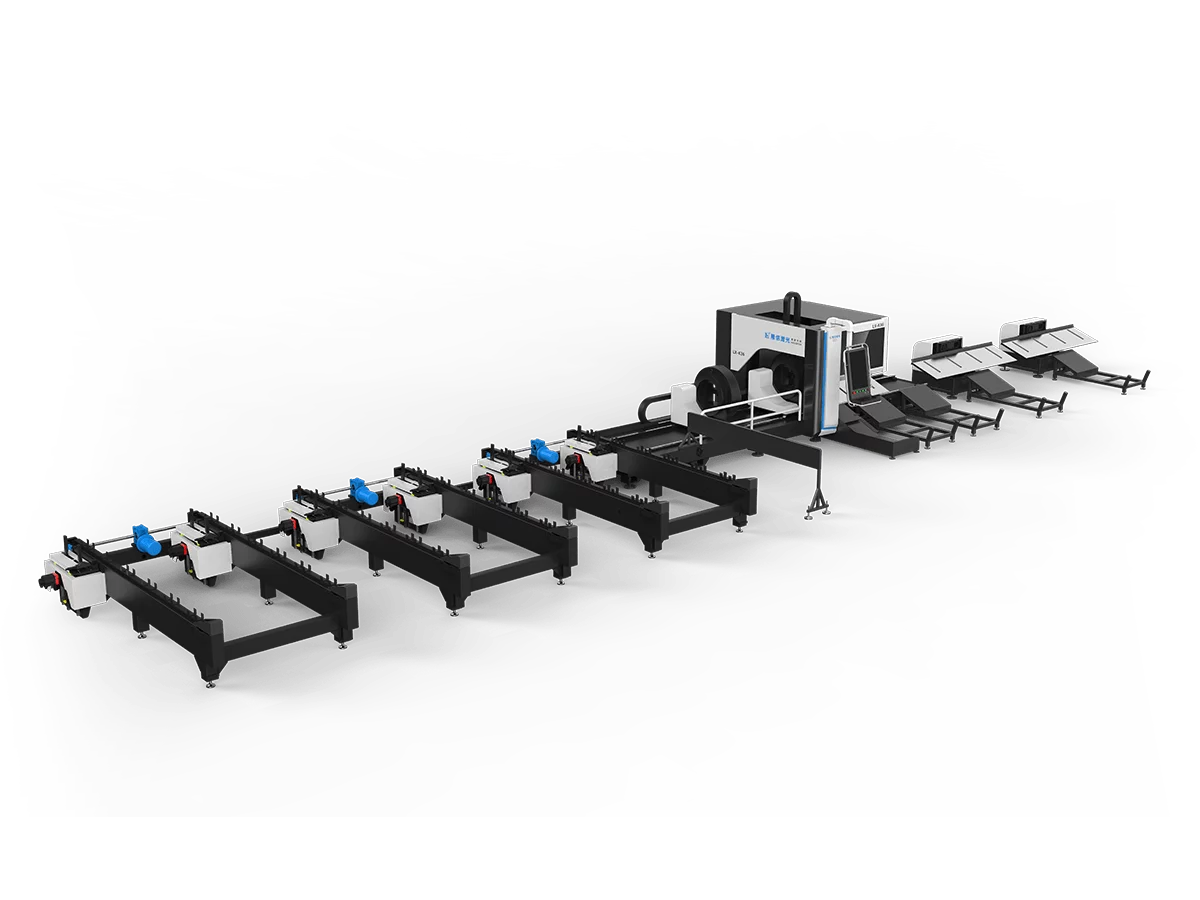

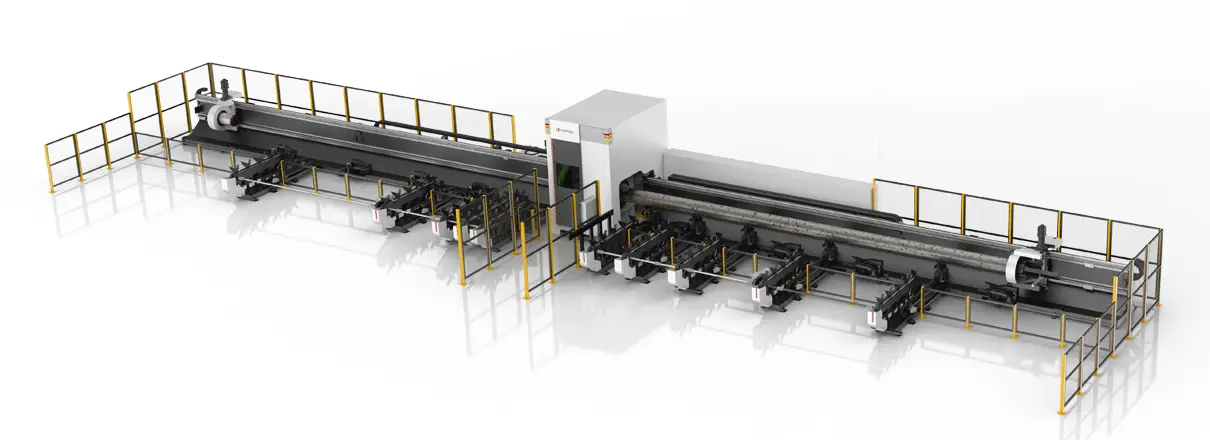

3. LONGXIN LASER

About the company:

Head Quarter: China

Established:2008

LONGXIN LASER is a giant in the global laser tube cutting machine industry. What sets LONGXIN apart from other manufacturers is its long-term focus on the research and innovation of tube cutting equipment and company.

Since 2013, Longxin has been all about laser tube cutting machines. They’re now the top dog in China, with 60% of the market. They’ve got over 30 models, making them a big player in the laser tube cutting equipment game.

LONGXINLASER is everywhere, helping 1,000+ users in 120+ countries. They have dealers in South Korea, Turkey, Brazil, Russia, and Mexico for top-notch service before and after sales, like installation and training. They also offer online help 24/7.

LONGXIN LASER makes laser tube cutting machines that are super fast and accurate. Their machines go 30% faster than other similar machines, reaching an acceleration of 1.5 G. This speed helps companies save money and get more work done.

There are a series of advanced pipe cutting technologies in LONGXIN. They use high-quality steel welding beds that have undergone a high-temperature stress-relieving annealing process. This treatment enhances the machines’ seismic resistance, rigidity, and stability. It is also one of the reasons why the machine can support high acceleration.

LONGXIN’s movable front chuck is a key technology that sets it apart. This feature allows the machine to lift the laser head for the final pipe cut, then the front chuck takes over to move the pipe forward for precise cutting of the tail end. Compared to other machines, which need at least 3 chucks for the same job, LONGXIN’s method reduces costs and processing time significantly.

Related products:

LX-K36 is the world’s first ultra-long 46 metre heavy-duty 3d 5-axis laser tube cutting machine. The equipment was delivered to the renowned South Korean shipbuilding company ACE E&T.

This laser tube cutting machine is super powerful with a 12 kW laser and can handle big metal tubes like I-beams and H-beams. It has cool features like bevel cutting and supports tubes up to 360mm in diameter. With its dynamic tube support and 20-meter loading system, it can cut with high precision for various types of metal tubes.

4. DNE LASER

About the company:

Head Quarter: China

Established:2008

Bystronic is a famous brand that makes laser machines in Switzerland. They have a company in Shenzhen, China called Bystronic dne.

In 2016, DNE LASER was entered into a joint venture with Bystronic Laser Group of Switzerland, resulting in a brand upgrade to “Bystronic DNE.”

Over the years of development, Bystronic DNE has become a professional provider of intelligent manufacturing system solutions, offering a range of equipment including laser cutting machines, laser tube cutting machines, CNC press brakes, and automation solutions.

After getting a boost from Bystronic’s investment, DNE LASER got their hands on some top-notch tech support, leading them to roll out a bunch of fresh laser tube cutting machines. This move helped DNE LASER make a name for themselves in the tube cutting scene over in China.

Related products:

D-Tube P 220 is a laser tube cutter by DNE. It can cut round tubes up to 220mm and profiles up to 145mm. It can do bevel cuts up to ±45° and has a water cooling system. You can also add an automatic loading system.

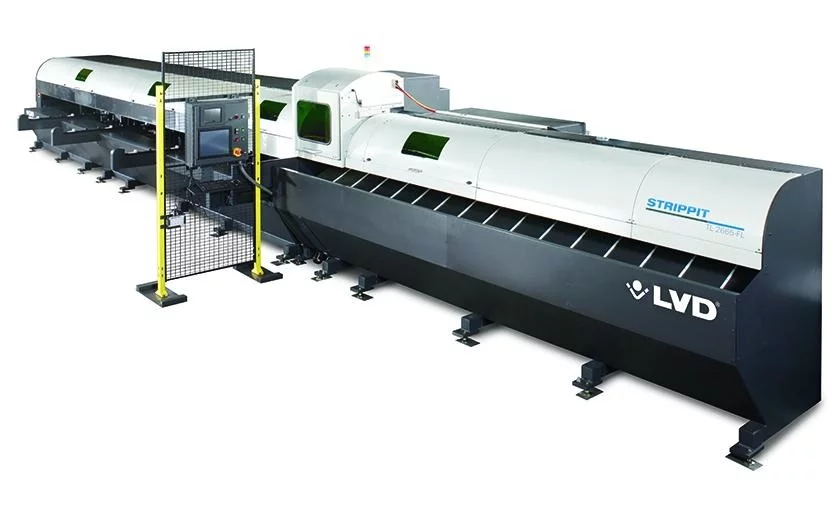

5. LVD Group

About the company:

Head Quarter: Belgium

Established:1952

LVD Group, well-known for their bending machines, expanded to include laser cutting machines in 1998 through an acquisition. By combining laser sheet metal cutting with stamping and bending technology, they have established themselves as a reputable company in the sheet metal fabrication equipment industry.

LVD makes laser cutting machines, press brakes, plate bending machines, punching machines, and shearing machines. They’ve grown and added more products. By buying AltaMAR and Pullmax AB, they made better single head punching machines.

Related products:

TL8525 and the TL2665 are the two laser tube cutting machine of LVD Group.

The TL8525 laser tube cutting machine is great for handling big tubes, supporting up to 250mm in diameter and an 8200 mm length for feeding. It’s designed specifically for round and square tubes.

The TL 2665 model is great for cutting small and medium tubes efficiently. It can handle tubes up to 7925 mm long and 165 mm in diameter. With a 7-position loader at the front, it’s easy to load tubes for big production runs. This machine can cut round, square, rectangular, and even oddly shaped tubes.

LVD group adopts Magazine-style front loader, bow detection, twist compensation and other technologies to ensure the accuracy and stability of pipe cutting.

6. JQ LASER

![]()

About the company:

Head Quarter: China

Established:2006

JQ Laser is an emerging manufacturer specializing in intelligent laser cutting equipment. Initially, JQ Laser primarily produced plate laser cutting machines. However, in recent years, the company has gradually shifted its focus to the field of laser pipe cutting machines.

JQ Laser offers a wide range of laser pipe cutting machine models, tailored to different pipe sizes, including large, medium, and small pipes, with the aim of achieving more precise cutting results.

Related products:

JQ Laser has incorporated three-dimensional five-axis cutting technology, originally used for plates, into pipe cutting processes, enabling the realization of three-dimensional pipe cutting.

7. HANSLASER

![]()

About the company:

Head Quarter: China

Established:1996

HANSLASER is a famous brand in China for making industrial laser stuff. They research, make, and sell laser machines and parts like laser markers, cutters, welders, and motion control pieces. They have a wide range of products.

Hanslaser has a good level of research and development. It has many patents in China. It is one of the few companies in the world that have mastered the UV laser patent technology.

Hanslaser has service locations in Asia, Europe and the Americas. Their main overseas markets are located in countries near China, such as Vietnam, Thailand, Malaysia, Philippines and India.

Hanslaser is good at cutting plates with lasers. Now, they have new laser tube cutters too. There are only a few models – high power and low power. These machines use Hans’s own CNC system, which works well with other Hans’s equipment.

Related products:

HS6522A is hanslaser’s main laser tube cutting machine. This machine supports pipe lengths of ≤6500mm. The cutting range is 15-220mm, and various shapes of tubes can be cut.

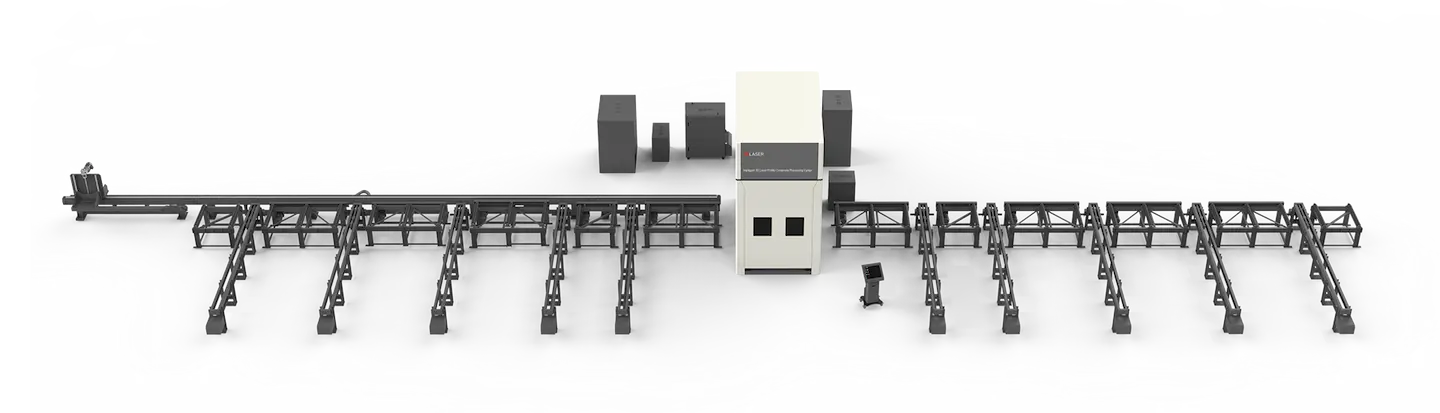

8. HGTECH

About the company:

Head Quarter: China

Established:1999

HGTECH is the earliest pioneer and leader in laser industrial applications in China. In the future, they are ready to comprehensively layout laser intelligent equipment.

HGTECH specializes in manufacturing various machines such as laser marking, welding, cleaning, and 3D printing machines. They have multiple research and development centers worldwide and operate through agency networks in countries like Germany, Poland, Hungary, Italy, Argentina, and Brazil.

Related products:

HGTECH’s top-of-the-line product is the TP12052F & LT12052F. This laser cutting machine is heavy-duty and comes with four chucks. It can handle tubes ranging from 20mm to 406mm in diameter, with lengths between 2200mm and 12000mm. Ideal for industries like bridges, ships, construction machinery, power towers, assembled buildings, and tunnel traffic, this machine is built to tackle tough jobs.

9. Bodor

About the company:

Head Quarter: China

Established:2008

Bodor Laser is a world-renowned laser processing intelligent solution provider integrating laser processing application product development, production, sales and service.

Bond Laser offers a variety of products that cater to different needs. They have laser cutting machines for plates, pipes, and profiles, as well as equipment for automating processes and welding. These machines come in various power ranges, from 1500W to 120000W.

Bodor independently develops the operating system, laser and laser head of the laser cutting machine. Innovate technology to create revolutionary value-enhancing experiences for customers.

Related products:

Bodor divides their laser pipe cutting machines into four series: M, T, K, and Q, which correspond to different levels.

The Q series laser pipe cutting machine is designed for cutting small pipes, while the K series and T series are laser pipe cutting machines with double chucks. The M series stands out as their main laser metal pipe cutting machines.

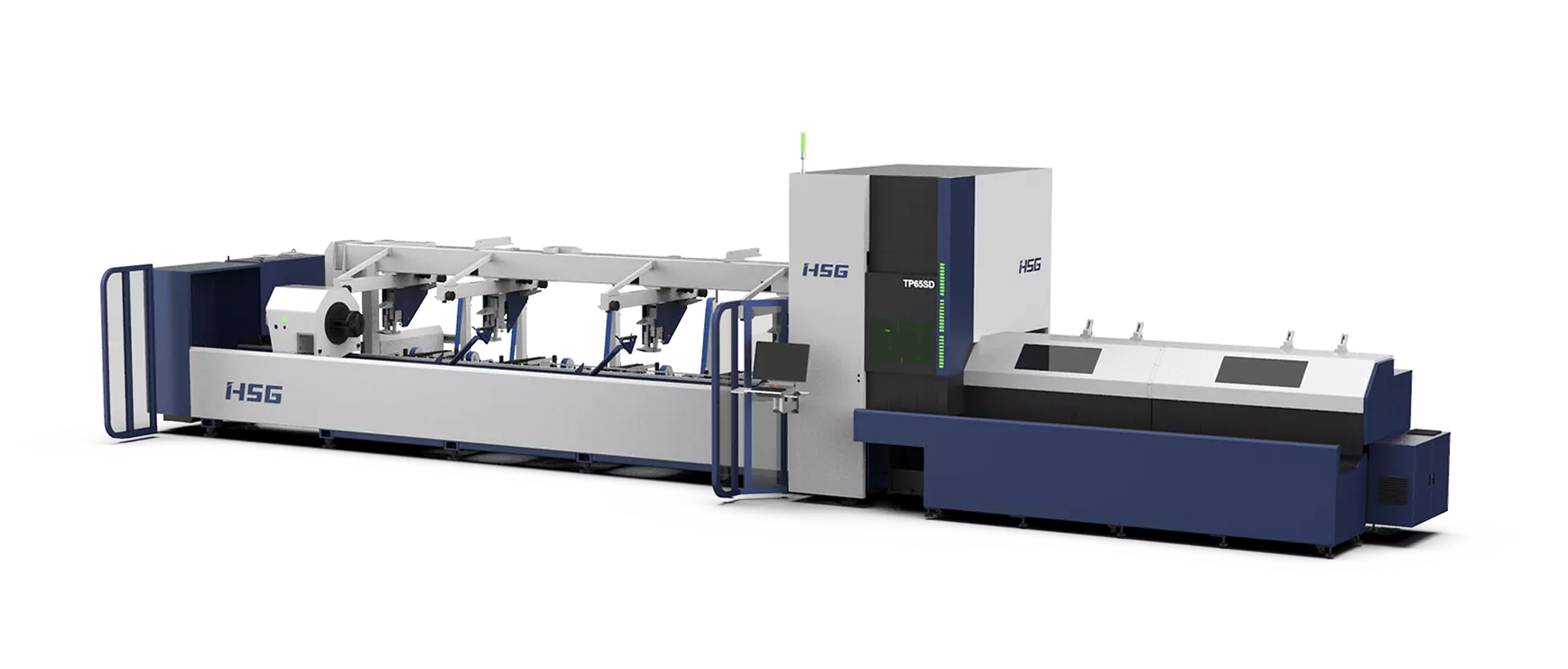

10. HSGLaser

![]()

About the company:

Head Quarter: China

Established:2006

HSG is also a company from China that integrates the research and development, production and sales of metal forming equipment. It is committed to providing metal forming equipment solutions to global users.

This high-tech company is a national enterprise that excels in research and development. With a strong presence in more than 100 countries and regions, it boasts 13 branches and over 30 service outlets worldwide, establishing a significant global reputation.

HSG’s laser pipe cutting equipment is quite comprehensive. They classify their machines based on the number of chucks.

Related products:

TPSD is HSG’s top laser pipe cutter. It can cut, weld, and tap threads on pipes. It works on round pipes from Φ20-273mm and square pipes from 20*20-200*200mm.

How to choose a laser tube cutting machine manufacturer?

1. Clarify needs:

Before making a purchase, it is important to determine the material, shape, diameter, thickness, and length of the tubes you need to process.

Also, consider the daily quantity of workpieces that need to be processed. Identify any additional special processing requirements, such as bevel cutting, threading, or tube bending processes.

2. Filter sellers:

If you’re new to buying a laser tube cutting machine, go for a well-known manufacturer like the ones mentioned in this list of top 10 brands. These companies have a variety of tube cutting options available for you to pick from.

If you want good help setting up and fixing your laser tube cutting machine later on, it’s best to go for brands that are closer to home.

3. Send inquiry:

When you’re buying big machines, it’s important to check prices from different companies. This helps you know what’s a good deal and pick the best one for you. Besides price, think about how good the companies are too.

Get to know each laser tube cutting machine manufacturer inside out. Check out their history, technical skills, customer support, reputation, service reach, and more. This way, you can pick the best manufacturer after considering all aspects of their business.

4. Face to face or video conference:

Consider setting up an interview or video call with the laser tube cutting machine manufacturer. This way, you can talk about your requirements more thoroughly and have a direct conversation with their sales team or technical experts.

You can reach out to the laser tube cutting machine manufacturers and ask for technical specs and initial price quotes. Inquire about the suppliers they work with and the machine’s key parameters.

5. Request a demo or factory tour:

Simply talking about it won’t cut it. You gotta get hands-on with samples and tests before making a purchase. This is how you see what the machine can really do in action.

Some companies, like LONGXIN LASER, might give you free sample cuts. But even if they don’t offer it for free, this cost is still important and shouldn’t be overlooked. You can either send your pipe samples through mail or ask them to purchase them on your behalf.

It’s a good idea to check out the manufacturer’s place yourself to make sure the sample cutting is up to par. If that’s not doable, you can ask the seller for an unedited video that shows the whole sample cutting process.

6. Inquire about after-sales service:

When you’re picking a laser tube cutting machine maker and getting ready to buy, make sure to ask about how they handle repairs and support after you’ve made the purchase.

For instance, the warranty length varies for different parts of the machine. Some sellers might promise a 5-year warranty, but this could only cover certain components like the laser and laser head that are less likely to get damaged.

When you buy a laser tube cutting machine, make sure the company has service centers and repair techs nearby. This helps you get quick help if your machine breaks down, reducing downtime.

By clicking Continue, you agree to LinkedIn’s User Agreement, Privacy Policy, and Cookie Policy.

Conclusion

Each of the top 10 laser tube cutting machine manufacturers brings something unique to the table in the diverse field of laser tube cutting. From unmatched precision to innovative solutions, these industry leaders are shaping the future of fabrication with their exceptional offerings.

So, use this info to start your research on LONGXINLASER for the latest laser tech. It’s just the beginning of your journey to excellence in laser tube cutting machines. Share our link where the future is being created.