Введение

Вы ищете лучшие бренды режущих головок для волоконных лазеров? Мы покажем вам 10 ведущих компаний с новейшими технологиями и высококачественной продукцией. Следите за обновлениями, чтобы узнать о лидерах отрасли по производству лазерных головок.

1. IPG Photonics (США)

IPG Photonics - ведущий мировой производитель волоконных лазеров и усилителей, основанный в 1990 году в Массачусетсе, США, известным экспертом по волоконной оптике доктором Валентином Гапонцевым.

За последние три десятилетия IPG выросла и стала крупнейшей в мире компанией по производству волоконных лазеров. Основной вид деятельности компании включает промышленные лазеры, медицинские лазеры и лазерные режущие головки, предназначенные для широкого спектра применений, таких как резка металла, сварка и медицинская эстетика.

IPG представила серию высокопроизводительных лазерных режущих головок. Ключевыми особенностями этих режущих головок являются их способность работать с чрезвычайно высокой мощностью лазера. FLC-30 может использовать мощность лазера непрерывного действия до 12 кВт, в то время как IPGCut-HP может обрабатывать лазер мощностью до 25 кВт. Это позволяет им резать металлические пластины различной толщины и из различных материалов, значительно расширяя области применения лазерной резки.

Еще одной отличительной особенностью является легкая и герметичная конструкция режущих головок. Прецизионная механическая конструкция и оптимизированный путь прохождения газа не только снижают вес для улучшения динамики системы, но и эффективно защищают оптические компоненты от пыли и загрязнений, обеспечивая длительную надежную работу.

Кроме того, режущие головки IPG интегрируют интеллектуальные функции мониторинга, такие как оптическая обратная связь по температуре в режиме реального времени, обнаружение краев и измерение давления. Эти возможности помогают поддерживать оптимальное расстояние между режущей головкой и обрабатываемой деталью, обеспечивая высокое качество и эффективность резки. Продукты также предлагают различные варианты электронной интеграции для удовлетворения индивидуальных потребностей различных клиентов.

2. Coherent (США)

Coherent - мировой лидер в области фотонных решений, предлагающий широкий спектр инновационных лазеров, оптики и систем лазерной обработки. Основанная более 50 лет назад, компания имеет прочное присутствие в различных отраслях промышленности.

Одним из ключевых направлений деятельности Coherent является линейка передовых лазерных режущих головок. Эти режущие головки предназначены для повышения точности, скорости и возможностей лазерной резки металла.

Режущая головка BIMO-FSC3 от Coherent - это выдающийся продукт, разработанный для обработки металлических листов толщиной до 50 мм, включая низкоуглеродистую сталь, нержавеющую сталь, латунь, медь и алюминий. Уникальная оптическая конструкция с большими фокусными расстояниями и диапазоном масштабирования обеспечивает превосходную производительность резки различных материалов и толщин. Эта режущая головка может работать с лазером мощностью до впечатляющих 30 кВт.

Для изготовления прецизионных деталей в таких отраслях, как бытовая электроника, медицинское оборудование и часовое дело, Coherent предлагает режущую головку SmartCut +. Совместимый с лазерами PowerLine FL, SmartCut + может создавать сложные микроструктуры в металлах, уменьшая конусность и увеличивая скорость обработки. Он обеспечивает не только традиционную воблерную резку, но и расширенные схемы сканирования, такие как спиральная и эллиптическая.

Coherent также предлагает интегрированные решения для лазерной маркировки, такие как система LFS / QFS с аксессуаром FLBK SC. Это позволяет быстро нанести лазерную маркировку на шатуны автомобильных двигателей перед гидравлическим растрескиванием, при этом маркировка каждой детали занимает менее одной секунды.

Благодаря гибкому модульному подходу к лазерной обработке система режущих головок Coherent FLBK60 может быть сконфигурирована для сварки, резки, сверления и маркировки, поддерживая мощность лазера до 3 кВт. Это универсальное решение обеспечивает превосходные результаты обработки для широкого спектра задач прецизионного производства.

Благодаря этому обширному ассортименту передовых лазерных режущих головок Coherent позволяет производителям автомобильной промышленности, электроники и других отраслей повысить производительность, качество и гибкость операций по обработке материалов.

3. Precitec (Германия)

Precitec - ведущий немецкий производитель высокопроизводительной оптики и головок для лазерной обработки. Компания Precitec, основанная в 1986 году со штаб-квартирой в Гаггенау, зарекомендовала себя как новатор в области промышленных лазерных технологий.

Одной из ключевых компетенций Precitec является ассортимент индивидуальных решений для лазерных режущих головок. Эти режущие головки предназначены для различных применений лазерной резки в 2D и 3D в различных отраслях промышленности.

Для двумерной резки плоского листового металла из стали, нержавеющей стали, алюминия и других сплавов компания Precitec предлагает свою серию ProCutter Thunder. Эти высокоскоростные автоматические режущие головки могут работать с мощностью лазера до 60 кВт, обеспечивая превосходное качество кромки и стабильность процесса.

Для сложной трехмерной лазерной резки пространственных геометрий ProCutter 2.0 от Precitec обеспечивает высокие динамические характеристики и исключительную точность. Это делает его хорошо подходящим для гибкой роботизированной резки, особенно в автомобильной отрасли.

SolidCutter - это высокопроизводительная роботизированная режущая головка Precitec, предназначенная для быстрого и надежного выполнения сложных задач 3D-резки в серийном производстве.

В диапазоне средней мощности FormCutter Plus представляет собой эффективное решение для 2D и 3D резки тонколистового металла с привлекательным соотношением цены и качества.

Благодаря усовершенствованной оптической конструкции станок FineCutter от Precitec обеспечивает точную лазерную резку тонких металлических листов и сложных 3D-деталей без заусенцев на кромках и отличную ширину щелей.

В основе этих режущих головок лежат интеллектуальные сенсорные технологии Precitec, которые обеспечивают стабильные и оптимизированные процессы резки для минимизации производственного брака.

Благодаря этому обширному ассортименту лазерных режущих головок Precitec дает производителям в таких отраслях, как машиностроение, автомобилестроение и прецизионное производство, возможность повысить производительность, гибкость и качество при лазерной обработке материалов.

4. Raytools (Швейцария)

Raytools - ведущий швейцарский производитель высокопроизводительной оптики и головок для лазерной обработки. Основанная в 2005 году со штаб-квартирой в Гларусе, Швейцария, компания зарекомендовала себя как инновационная сила в области промышленных лазерных технологий.

Ключевым направлением деятельности Raytools является широкий ассортимент решений для лазерных режущих головок. Эти режущие головки предназначены для выполнения различных задач 2D и 3D лазерной резки в различных отраслях промышленности.

Raytools предлагает серию BD для автоматической 2D-резки плоского листового металла из стали, нержавеющей стали, алюминия и других сплавов. Эти высокоскоростные головки для резки труб выпускаются мощностью 4 кВт и 8 кВт, что обеспечивает стабильное качество резки и характеристики кромок.

Серия BD также может быть оснащена внешним моторизованным направляющим по оси Z, что делает их хорошо подходящими для применения в легких роботизированных системах резки. Такая интеграция режущей головки с внешней осью обеспечивает повышенную гибкость и динамические характеристики.

Переходя к 2D-резке плоского листового металла, режущие головки серии BM от Raytools имеют широкий диапазон мощности от 3,3 кВт до 12 кВт. Модели BM111E и BM114E оснащены интеллектуальными сенсорными технологиями, обеспечивающими мониторинг процессов и управление ими в режиме реального времени с помощью EtherCAT-связи.

Что касается высокомощных режущих головок серии BM115, то они рассчитаны на работу с лазером мощностью до 12 кВт, обеспечивая возможности резки на полную мощность. Эти усовершенствованные режущие головки обеспечивают оптимальное качество кромки и стабильность процесса даже при экстремальных уровнях мощности.

Чтобы обеспечить по-настоящему интегрированное интеллектуальное решение, Raytools разработала режущие головки серии BS “все в одном”. Линейка BS мощностью от 4 до 20 кВт оснащена комплексной интеграцией датчиков, что позволяет осуществлять мониторинг и управление в режиме реального времени через мобильное приложение или интерфейс ЧПУ. Эта интеллектуальная технология позволяет пользователям оптимизировать процессы лазерной резки и повысить производительность.

Завершают ассортимент режущие головки Raytools с ручной фокусировкой, такие как BT220RC и BT240S. Эти экономичные решения подходят для более легких задач лазерной резки, включая роботизированные приложения, где автоматическое управление фокусировкой не является обязательным.

В основе этих режущих головок лежит запатентованный оптический дизайн Raytools и производственные возможности. Компания также сотрудничает с мощной сетью академических и промышленных партнеров, постоянно внедряя инновации и расширяя границы технологий лазерной обработки.

5. Лазерные механизмы (США)

Laser Mechanisms, Inc. является ведущим производителем передовых лазерных обрабатывающих головок и систем подачи луча для широкого спектра промышленных применений. Основанная более 30 лет назад, компания зарекомендовала себя как надежный партнер для ведущих интеграторов лазерных систем и конечных пользователей по всему миру.

В основе ассортимента продукции Laser Mechanisms лежат серии FiberCut®, FiberMINI®, FiberWELD® и AccuFiber™ – инновационные обрабатывающие головки, разработанные для максимального повышения производительности и универсальности волоконных лазерных систем. Эти продукты демонстрируют инженерный опыт компании Laser Mechanisms и стремление предоставлять надежные и удобные в использовании решения.

Серия FiberCut® предлагает ряд режущих головок, которые могут работать с волоконным лазером мощностью до 4 кВт, с такими функциями, как автоматическое управление отводом, герметичные пути прохождения луча и легкие конструкции, оптимизированные для роботизированной интеграции. Линейка FiberMINI® представляет собой гибкую, компактную платформу для резки и сварки по привлекательной цене. В то же время серия FiberWELD® решает задачи сварки высокой мощности благодаря расширенным возможностям мониторинга и управления сварным швом.

Для самых требовательных применений модульные головки AccuFiber™ обеспечивают точную фокусировку луча и неограниченные возможности настройки. Линейка AccuFiber ™ с возможностью резки, сварки и даже аддитивного производства демонстрирует возможности лазерных механизмов по разработке индивидуальных решений для подачи луча.

Помимо обрабатывающих головок, ассортимент Laser Mechanisms включает широкий спектр приборов для диагностики луча, измерения фокуса и контроля мощности. Этот комплексный набор дополнительных продуктов позволяет компании предлагать комплексные решения для лазерной обработки материалов.

Располагая глобальной сетью продаж и технической поддержки, Laser Mechanisms стремится помогать своим клиентам достигать их целей в области производительности и качества. Инновационный дух компании, опыт применения и стремление к успеху клиентов сделали ее надежным партнером для ведущих производителей лазеров и конечных пользователей по всему миру.

6. LT Ultra (Германия)

LT Ultra - ведущий немецкий производитель высокоточных лазерных обрабатывающих головок и решений для наведения луча. Компания, базирующаяся в Хердванген-Шенахе, имеет более чем 30-летний опыт разработки инновационных технологий для сложных задач лазерной обработки материалов.

Передовые 2D и 3D лазерные обрабатывающие головки LT Ultra составляют основу ассортимента ее продукции. Головки для 2D сварки CO2 имеют модульную конструкцию с водяным охлаждением, обеспечивающую выдающееся качество обработки и производительность. Для 3D-приложений компания предлагает наклонные и поворотно-наклонные головки, которые обеспечивают исключительную точность и долговечность благодаря сверхточному проектированию.

В дополнение к обрабатывающим головкам LT Ultra предлагает полный набор компонентов для наведения луча – от отклоняющих модулей до поворотных столов. Это позволяет компании поставлять комплексные индивидуальные решения заказчикам по всему миру.

Технологическое лидерство LT Ultra основано на стремлении к инновациям и успеху клиентов. Компания оказывает клиентам поддержку в разработке приложений, услугах по модернизации и обучении для обеспечения оптимальной производительности лазерной обработки.

7. Трумпф (Германия)

TRUMPF - всемирно известная немецкая компания в области промышленных технологий, наиболее известная своими ведущими в отрасли лазерными системами и решениями для обработки листового металла. Компания TRUMPF со штаб-квартирой в Дитцингене обладает более чем 75-летним опытом внедрения инноваций в мире лазеров.

В основе лазерного ассортимента TRUMPF лежат передовые обрабатывающие головки. Эти специализированные компоненты имеют решающее значение для направления и формирования лазерного луча, что позволяет выполнять высокоточную резку, сварку, сверление и другие виды обработки материалов.

Передовые технологические головки TRUMPF используют глубокий опыт компании в области оптики, мехатроники и автоматизации. Такие модели, как BEO D70 и BEO D80, оснащены инновационными системами наведения луча и фокусировки, которые обеспечивают непревзойденное качество резки и скорость обработки.

Для 3D-приложений TRUMPF предлагает ряд наклонных и поворотных головок, которые позволяют выполнять сложные многомерные лазерные операции. К ним относятся TruLaser Robot 5020 и TruLaser Cell 7040, которые сочетают в себе усовершенствованную конструкцию головки и высокоточное роботизированное управление движением.

Помимо аппаратного обеспечения, TRUMPF оснащает свои обрабатывающие головки комплексным программным обеспечением и решениями для оцифровки. Это позволяет производителям оптимизировать параметры лазера, контролировать процессы и повышать производительность.

8. Ханслейзер (Китай)

Основанная в 1996 году со штаб-квартирой в Шэньчжэне, Китай, Han's Laser Technology Group прочно зарекомендовала себя как мировой лидер в области промышленного лазерного производства. Публично торгуемая компания стала публичной на Шэньчжэньской фондовой бирже в 2004 году и с тех пор выросла, превратившись в мощную индустриальную компанию стоимостью 7 миллиардов долларов.

Используя более чем 25-летний опыт работы в области лазерной промышленности, компания Han's Laser разработала широкий ассортимент промышленных лазерных решений, включая не только режущие головки, но и лазерную маркировку, сварку, микрообработку и роботизированные системы. Такой разнообразный ассортимент продукции позволяет компании обслуживать широкий спектр отраслей промышленности, от электроники и автомобилестроения до медицинского оборудования и аэрокосмической отрасли.

Лазерные режущие головки мирового класса для повышения производительности

В основе предложений Han's Laser лежат усовершенствованные лазерные режущие головки, разработанные для обеспечения выдающейся производительности, надежности и универсальности. Эти передовые продукты являются результатом значительных инвестиций компании в исследования и разработки, на их имя выдано более 5700 патентов и десятки авторских прав на программное обеспечение.

Режущие головки Han's Laser обладают рядом передовых функций, включая автоматическую регулировку фокуса для равномерной резки толстых пластин, компактную оптическую конструкцию и конструкцию воздушного потока для повышения скорости и качества, надежную герметизацию класса IP6 для защиты критически важной оптики и интеллектуальный мониторинг температуры, давления и загрязнения линз для оптимальной производительности.

Приверженность Han's Laser инновациям демонстрируется разнообразной линейкой режущих головок, которая включает в себя мощную волоконно-оптическую головку HAC08 для обработки толстых листов, эффективную волоконно-оптическую головку HC20, оптимизированную для резки тонких и средних листов, универсальную 5-осевую 3D головку RC304, которая открывает передовые возможности обработки деталей, и надежную трубную режущую головку HC03-T. для прецизионного изготовления труб.

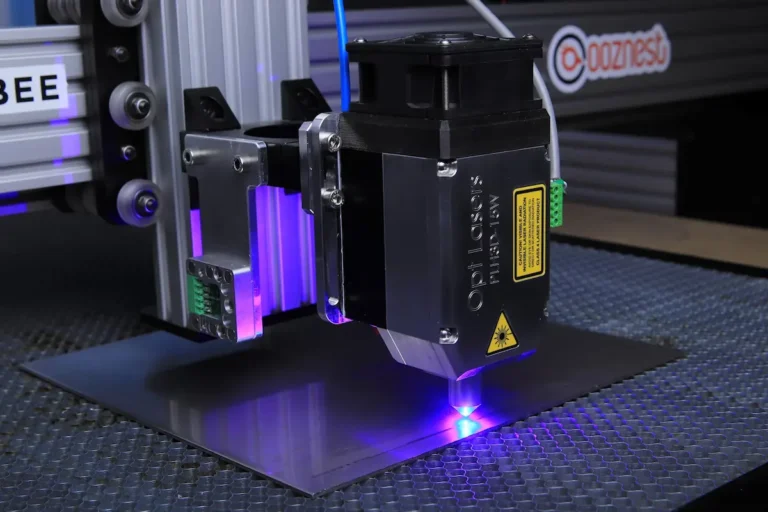

9. Оптические лазеры (Польша)

Opt Lasers - динамично развивающийся бренд, принадлежащий польской компании Tomorrow's System Sp. z o.o. Основанная в 2014 году со штаб-квартирой в Варшаве, Opt Lasers является ведущим европейским производителем высококачественных оптических и электронных устройств. Компания специализируется на поставке компактных режущих и гравировальных лазерных головок для станков с ЧПУ и 3D-принтеров, трансформируя лазерную промышленность и производственные линии с ЧПУ.

Ассортимент продукции Opt Lasers включает широкий спектр решений промышленного класса, включая лазерные головки для резки и гравировки, стандартные и изготовленные на заказ лазерные модули, драйверы лазерных диодов и регуляторы температуры. Как OEM-производитель, компания использует свои обширные возможности определения характеристик лазера, предлагая лазерные модули, адаптированные для интеграции в более крупные системы в различных областях применения.

В основе предложений Opt Lasers лежат усовершенствованные лазерные режущие головки, в которых используются коротковолновые синие лазерные диоды. Эти “Компактные лазерные головки” отличаются высоким поглощением света, низким энергопотреблением, низкими затратами на техническое обслуживание и компактными размерами, что позиционирует их как готовое решение для производственной отрасли.

Лазерные режущие головки Opt Lasers, такие как PLH3D-XT8, PLH3D-XT-50 и PLH3D-6W-XF +, обеспечивают оптическую мощность в диапазоне от 45 Вт до 0,5 Вт. Эти высокопроизводительные решения обеспечивают эффективную резку и гравировку широкого спектра материалов, включая металлы, пластмассы и дерево. Благодаря высокому разрешению, плотности мощности и эффективности использования энергии режущие головки Opt Lasers подходят для применения в таких областях, как точная художественная гравировка, высокоскоростная гравировка и резка толстых материалов.

10. Бочу (Китай)

Компания BOCHU, основанная в 2008 году, является поставщиком решений для автоматизации, специализирующимся на лазерной резке, сварке, микрообработке и других передовых областях производства.

BOCHU в первую очередь занимается исследованиями и разработкой продуктов в области автоматизации лазерной обработки. Компания самостоятельно разработала программное обеспечение для лазерной резки и управления раскроем труб, а также программные решения для раскроя и оптимизации.

BOCHU предлагает широкий ассортимент продукции, включая системы ЧПУ для лазерной резки FSCUT серии, охватывающие широкий диапазон уровней мощности и типов труб, промышленное программное обеспечение для интеллектуальных заводов, решение для автоматизации сварки FSWELD и системы ЧПУ для прецизионной обработки. Используя продукты собственной разработки, компания продолжает расширять сферу своего бизнеса.

Серия лазерных режущих головок BOCHU включает в себя интеллектуальные режущие головки серии BLT, включающие экономичные BLT310 для средне- и маломощных применений (≤4 кВт) и высококачественные модели BLT441T / BLT461T для резки мощностью 15 кВт / 20 кВт.

Компания также предлагает системы 3D-резки, такие как интеллектуальная система резки FSCUT9200 для обработки стальных конструкций и профессиональная система FSCUT9100 для резки с плоским скосом.

Для резки труб компания BOCHU предлагает комплексные системы FSCUT5000A / B для тяжелых условий эксплуатации и модели FSCUT3000DE / S для резки труб среднего и мелкого размера.

В области плоскорезной резки ассортимент продукции компании включает системы smart bus FSCUT8000 / 6000 для резки с высокой мощностью и системы FSCUT4000E/2000E /2000C /1000S на базе карт / шин для резки со средней и низкой мощностью.

Такой широкий ассортимент режущих головок и системных решений позволяет BOCHU удовлетворять разнообразные требования клиентов из различных отраслей промышленности.

Подводим итоги

При поиске лучшей лазерной головки важно знать, на что обращать внимание и какие бренды являются лучшими. Убедитесь, что лазерная головка соответствует вашим потребностям, проверив ее качество, точность, долговечность и отзывы клиентов. Это поможет вам сделать правильный выбор.

Теперь, когда вы знаете эти важные вещи, пришло время купить первоклассную лазерную головку, чтобы улучшить ваши проекты. Работаете ли вы в промышленности или просто любите заниматься рукоделием, выбор высококачественной лазерной головки улучшит вашу работу. Выбирайте внимательно, и ваши проекты будут выглядеть потрясающе!