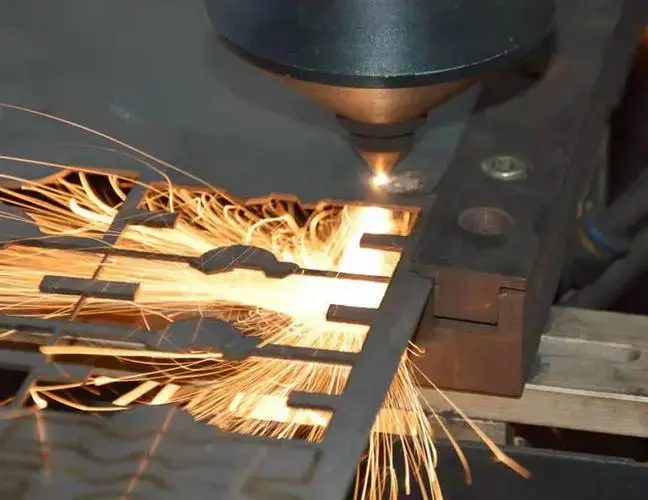

Pemotongan aluminium dengan laser menghadirkan tantangan yang unik karena reflektifitas dan konduktivitas termalnya yang tinggi. Dalam blog ini, kami akan mempelajari aspek-aspek penting dari pemotongan aluminium dengan laser, mendiskusikan tantangan yang ditimbulkan oleh material dengan daya pantul tinggi, dan mengeksplorasi beberapa solusi inovatif.

Memahami Tantangan

Reflektifitas dan Penyerapan

Reflektifitas tinggi aluminium (80%-90%) secara signifikan memengaruhi efisiensi pemotongan laser. Tidak seperti bahan dengan reflektifitas yang lebih rendah, aluminium memantulkan sebagian besar sinar laser, sehingga mengurangi tingkat penyerapan. Penyerapan yang rendah ini mempersulit untuk mendapatkan potongan yang bersih dan meningkatkan keausan pada peralatan pemotongan laser.

Refleksi Belakang

Salah satu masalah utama dalam memotong bahan dengan daya pantul tinggi seperti aluminium adalah potensi kerusakan akibat pantulan balik. Apabila sinar laser tidak menembus material, sinar laser yang dipantulkan dapat kembali ke sumber laser, sehingga menyebabkan potensi kerusakan. Masalah ini memerlukan penggunaan peralatan dan teknik khusus untuk mengurangi risiko.

Peralatan dan Teknik untuk Memotong Aluminium

1. Laser Cahaya Biru

Laser cahaya biru, yang beroperasi pada panjang gelombang 400-500 nm, telah menunjukkan harapan dalam memotong bahan dengan reflektifitas tinggi. Tidak seperti laser CO2 tradisional yang beroperasi dalam spektrum inframerah, laser cahaya biru menawarkan tingkat penyerapan yang lebih baik untuk bahan seperti tembaga dan aluminium. Laser ini membutuhkan daya yang lebih rendah (400-800 watt dibandingkan dengan 4000 watt yang dibutuhkan untuk laser CO2) dan menghasilkan lebih sedikit percikan dan pemotongan yang lebih bersih.

2. Kepala Keluaran Serat yang Dioptimalkan

Untuk mengatasi masalah pantulan ke belakang, sebagian sistem pemotongan laser dilengkapi dengan kepala keluaran serat yang dioptimalkan. Kepala ini mencakup fitur-fitur seperti perangkat penghilang pantulan balik dan sistem pendingin air untuk melindungi sumber laser dari cahaya yang dipantulkan. Misalnya, kepala keluaran serat QBH oleh Raycus Laser mengintegrasikan sistem penghilang pantulan untuk menangani pantulan intens dari bahan dengan reflektifitas tinggi.

3. Gas Bantu

Menggunakan gas bantu yang tepat sangat penting untuk menghasilkan potongan yang bersih. Nitrogen atau gas inert lebih disukai untuk aluminium untuk mencegah oksidasi dan menjaga kualitas potongan. Gas-gas ini juga membantu menghilangkan material cair dari area pemotongan, sehingga meningkatkan kualitas potongan secara keseluruhan.

4. Pemotongan Laser Pulsa

Pemotongan laser pulsa melibatkan penggunaan semburan sinar laser berenergi tinggi yang pendek untuk memotong bahan. Teknik ini sangat efektif untuk memotong aluminium karena mengurangi zona yang terpengaruh panas (HAZ) dan meminimalkan risiko lengkungan material. Kontrol yang tepat dari pulsa laser juga membantu dalam mencapai pemotongan yang lebih bersih dan kualitas tepi yang lebih baik.

5. Teknik Pembentukan Balok

Teknik pembentukan sinar yang canggih, seperti penggunaan elemen optik difraksi (DOE) dan pembentukan sinar multi-mode, dapat meningkatkan efisiensi pemotongan aluminium dengan laser. Teknik-teknik ini membantu mendistribusikan energi laser secara lebih merata ke seluruh material, mengurangi titik panas dan meningkatkan kualitas pemotongan secara keseluruhan.

6. Laser Serat Daya Tinggi

Laser serat berdaya tinggi, biasanya berkisar antara 6 kW hingga 12 kW, telah menjadi semakin populer untuk memotong lembaran aluminium yang tebal. Laser ini menawarkan efisiensi dan presisi yang tinggi, sehingga memungkinkan kecepatan potong yang lebih cepat dan kualitas tepi yang lebih baik. Penggunaan laser berdaya tinggi juga membantu mengurangi waktu pemrosesan secara keseluruhan.

7. Sistem Pemotongan Laser Hibrida

Sistem pemotongan laser hibrida menggabungkan manfaat dari berbagai jenis laser, seperti CO2 dan laser serat, untuk mengoptimalkan proses pemotongan aluminium. Sistem ini dapat beralih di antara sumber laser yang berbeda tergantung pada bahan dan ketebalan, sehingga memberikan fleksibilitas dan efisiensi yang lebih besar.

8. Optik Adaptif

Teknologi optik adaptif memungkinkan penyesuaian secara real-time pada fokus dan bentuk sinar laser berdasarkan karakteristik material dan kondisi pemotongan. Teknologi ini membantu mempertahankan performa pemotongan yang optimal dan meningkatkan kualitas pemotongan secara keseluruhan.

Parameter Utama untuk Aluminium Pemotongan Laser

Kekuatan Laser

Memilih daya laser yang tepat sangatlah penting. Meskipun daya yang lebih tinggi diperlukan untuk bahan yang lebih tebal, namun menggunakan daya yang berlebihan dapat menyebabkan pelelehan dan kualitas potongan yang buruk. Sangatlah penting untuk menemukan keseimbangan yang sesuai dengan ketebalan bahan dan kualitas potongan yang diinginkan.

Kecepatan Pemotongan

Kecepatan potong harus dioptimalkan untuk mencegah penumpukan panas yang berlebihan, yang dapat memengaruhi kualitas potongan dan menyebabkan lengkungan. Pada umumnya, kecepatan yang lebih lambat menghasilkan kualitas potongan yang lebih baik, tetapi dapat meningkatkan waktu pemrosesan.

Kualitas Fokus dan Sinar

Pemfokusan sinar laser yang tepat sangatlah penting. Titik fokus yang lebih kecil menghasilkan densitas energi yang lebih tinggi, sehingga menghasilkan pemotongan yang lebih baik. Memastikan bahwa sinar laser terfokus secara tepat pada permukaan material sangat penting untuk menghasilkan potongan yang bersih.

Pasca-Pemrosesan dan Jaminan Kualitas

Menghapus Sampah

Setelah memotong, sangat penting untuk membuang sampah (bahan sisa) dari bagian tepi untuk memastikan hasil akhir yang mulus. Hal ini bisa dilakukan dengan menggunakan alat atau kikir deburring.

Pemeriksaan Akhir

Lakukan pemeriksaan menyeluruh untuk memastikan bahwa hasil pemotongan memenuhi spesifikasi dan standar kualitas yang dipersyaratkan. Setiap penyimpangan harus diatasi dengan menyesuaikan parameter pemotongan.

Pendekatan Inovatif untuk Material dengan Reflektifitas Tinggi

Aplikasi Laser Cahaya Biru

Laser sinar biru semakin banyak digunakan dalam aplikasi yang membutuhkan presisi tinggi dan dampak termal minimal, seperti pengelasan baterai lithium-ion dan pembuatan komponen elektronik. Kemampuannya untuk memproses bahan dengan reflektifitas tinggi secara efisien menjadikannya alat yang berharga dalam industri ini.

Kepala Keluaran Serat Tingkat Lanjut

Dengan menggabungkan desain canggih pada kepala keluaran serat, produsen dapat secara signifikan mengurangi risiko kerusakan akibat pantulan balik. Inovasi ini memungkinkan pemrosesan yang lebih aman dan lebih efisien untuk bahan dengan daya pantul tinggi, seperti aluminium.

Kesimpulan

Pemotongan aluminium dengan laser memerlukan pertimbangan yang cermat terhadap berbagai faktor, termasuk reflektifitas, daya laser, kecepatan pemotongan, dan penggunaan gas bantu. Dengan memanfaatkan teknologi baru seperti laser cahaya biru, kepala keluaran serat yang dioptimalkan, dan teknik pembentukan sinar yang canggih, adalah mungkin untuk mengatasi tantangan dan mencapai pemotongan berkualitas tinggi. Karena industri pemotongan laser terus berkembang, menguasai pemotongan bahan reflektifitas tinggi seperti aluminium akan membuka peluang dan aplikasi baru.