What is tube and plate laser cutting machine?

Tube and plate laser cutting machine all known as sheet and tube laser cutting machine, fiber laser cutting machine for sheets and tubes.

Integrated plate and pipe laser cutting machines, due to their ability to handle both plates and pipes, combined with their high precision, high speed, and good cost-performance ratio, are seeing increasingly widespread application in industrial production.

Integrated plate and pipe laser cutting machines can achieve seamless cutting of metal pipes, stainless steel pipes, aluminum alloy pipes, steel pipes, carbon steel pipes, alloy pipes, aluminum pipes, copper pipes, as well as cutting of stainless steel plates and aluminum plates, including circular holes, square holes, and irregular shapes.

How does a tube and plate laser cutting machine work?

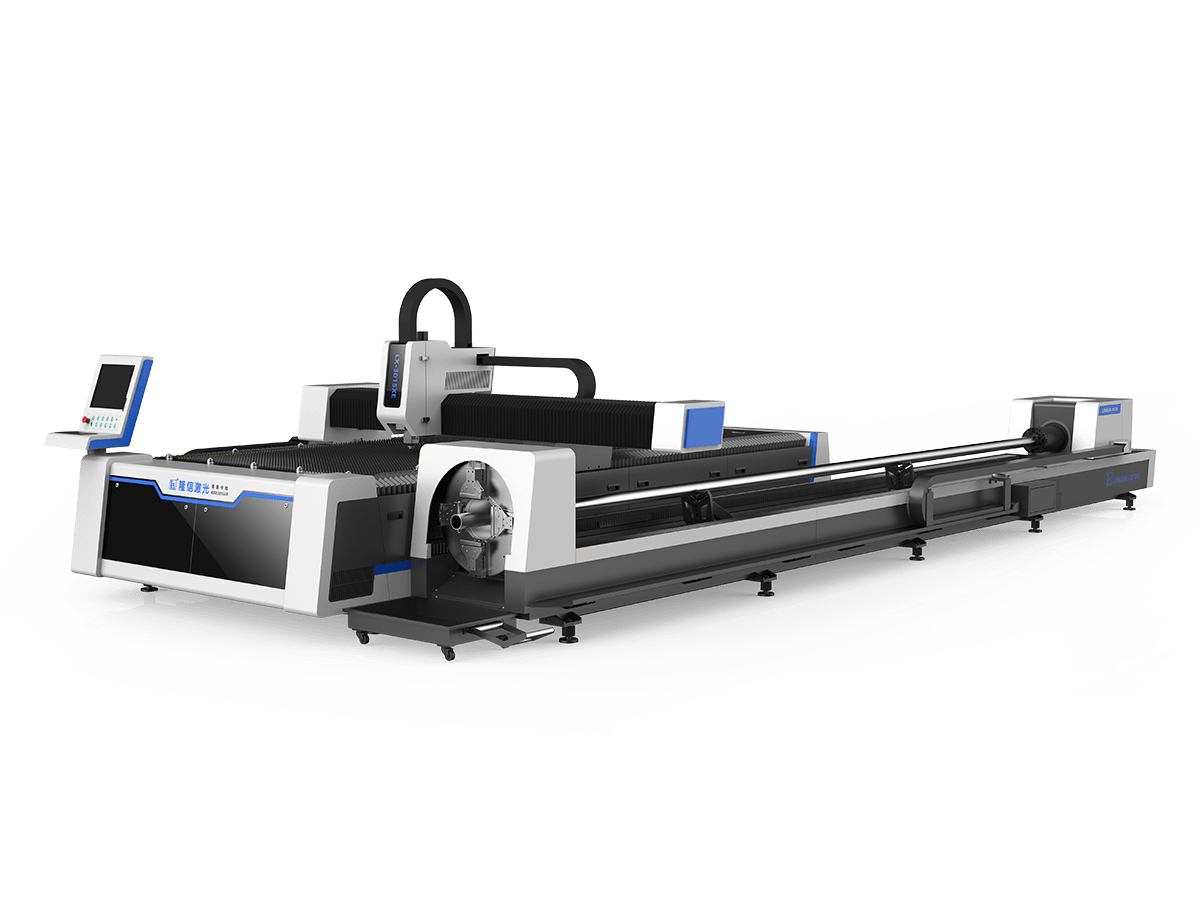

The machine design of the tube and plate laser cutting machine is rather unique, but not overly complex to understand. Its main components include a plate cutting platform, a CNC control system, servo drive motors, a pipe material support lathe, pipe clamping chucks, and a movable laser cutting head assembly.

It looks like a standard laser cutting machine for plates, but with an additional linear guideway lathe system installed alongside it for cutting pipe and tube materials. When tube cutting is required, the control system can be used to move the laser head over to the tube platform for cutting. The tube cutting section can use a pneumatic chuck with a rotational structure. It can automatically adjust the clamping force based on factors like the tube type, diameter, and wall thickness.

The tube cutting section of a typical tube and plate laser cutting machine tends to have a relatively simple structure. It is usually equipped with just a single chuck, and most do not have an automatic loading device.

Advantages of tube and plate laser cutting machine

Dual-purpose: A single machine can simultaneously meet the processing requirements for both sheet materials and pipe materials, increasing the space utilization rate by 50%.

Precision Clamping: Using an intelligent pneumatic chuck, the pipe position is automatically located, enabling precise cutting.

Intelligent Control System: A CNC system specifically designed for tube and plate laser cutting machines, featuring a visualization-based operating interface and support for importing various file formats.

Smooth Operation, Minimal Deformation: The machine tool has undergone high-temperature annealing to eliminate residual stress, enabling smoother operation and improving cutting precision.

Cost-Effective: For startups or factories with low processing volumes, the tube and plate laser cutting machine is a cost-saving choice.

Who is tube and plate laser cutting machine suitable for?

Tube and plate laser cutting machine is suitable for customers who have processing needs for both metal plates and pipes. However, the machine is actually more advantageous in plate cutting, and is more suitable for customers whose demand for pipe processing is not high, but occasionally need it as well.

Since the design of the tube and plate laser cutting machine is originally aimed at being compact and taking up little space, if the configuration for pipe cutting is further improved to enhance precision and add more cutting processes, it will result in the machine becoming larger in size, making a simple matter more complicated.

Therefore, if you have specific requirements on pipe cutting in terms of processes, precision, throughput, and speed, it is better to buy a dedicated laser tube cutting machine, rather than this integrated machine that handles both plates and pipes.