Pipe cutting machines are vital tools in the industrial sector, simplifying the process of cutting or slicing pipes and tubes to achieve clean and precise cuts. These machines not only make the cutting process quicker and more convenient but are also classified into two primary categories: cold cutting and hot cutting methods. Cold cutting machines, preferred in hazardous environments due to their safety features and lack of airborne contamination, include pneumatic and hydraulic types, while hot cutting techniques—encompassing gas, plasma, and laser cutting—utilize heat to slice through materials of varying thicknesses efficiently.

This comprehensive guide aims to explore the diverse types of tube cutting machines, from manual tube cutters that offer portability and affordability, to advanced laser tube cutting machines sought after by tube laser cutting machine manufacturers for their speed and precision.

1. Portable manual pipe cutter

A type of cold cutting. Portable manual pipe cutters are renowned for their simplicity and effectiveness in cutting various types of pipes, including EMT conduit, copper, brass, aluminum, and PVC. These tools are particularly valued for their precision and ease of use in environments where portability is key.

Features

- Design and Materials: Typically, these cutters are designed to handle pipe diameters ranging from 1/8 inch to 1 1/8 inch. They are compact and require manual operation, which involves a straightforward process of clamping the pipe and rotating the cutter around it.

- Use method: To achieve a clean cut, the pipe is marked at the desired measurement, the cutter’s knob is loosened, and the pipe is placed within the cutter. After aligning the cutter wheel with the mark, the user tightens the knob and rotates the cutter around the pipe, gradually tightening the knob further until the cut is complete.

- Post-Cutting Process: Once the cut is made, a deburring tool, often built into the cutter, is used to remove any burrs or lips inside the end of the conduit, ensuring a smooth finish.

Advantages

- Cost-Effectiveness: Compared to more complex machinery, portable manual tube cutters are relatively inexpensive.

- Ease of Use: Their simple mechanism makes them easy to operate, even for individuals without extensive technical training.

- Safety and Compactness: These tools are safe to use, with a lower risk of injury compared to power tools. Their small size makes them easy to transport and store.

Limitations

- Physical Effort: While they are simple to use, manual tube cutters require physical effort, which might not be ideal for large-scale projects.

- Material Limitations: They are best suited for thin-walled pipes. Thicker or harder materials might require more robust cutting solutions.

Portable manual tube cutters offer a practical solution for small-scale or on-the-go cutting tasks. They balance cost, convenience, and functionality, making them a staple in many toolkits for quick and efficient pipe cutting.

2. Circular saw machine

A type of cold cutting. Circular saw machine, also known as a circular saw, is a power tool primarily used for cutting wood, metal, and other materials. The core of the circular saw tube cutting machine is a high-speed rotating circular saw blade. This blade is driven by a powerful electric motor or gasoline engine, spinning at thousands of revolutions per minute. When the user pushes the workpiece (such as a metal tube) towards the rotating saw blade, the sharp teeth on the blade will cut through the workpiece, allowing for fast and precise cutting.

Advantages

- Lower Cost: The equipment and operating costs are generally lower for circular saws.

- Simpler Operation: Circular saw machines are easier to operate and maintain compared to laser systems.

- Improved Safety: Circular saws do not involve laser hazards, making them a safer option.

Limitations

- Limited Cutting Depth: Circular saws are typically limited to cutting depths of around 2-3 inches, depending on the blade size. They may struggle with thicker or larger diameter tubes.

- Blade Wear and Replacement: The circular saw blades will dull over time and need to be frequently replaced, adding ongoing maintenance costs.

- Noise and Vibration: Circular saws operate at high speeds and can generate significant noise and vibration during use, which can be fatiguing for operators.

- Burrs and Burr Formation: While circular saws can produce clean cuts, there is still potential for some burr or edge imperfections to form on the cut surfaces.

- Material Limitations: Circular saws work best for cutting straight, linear cuts on relatively homogeneous materials like metals and wood. They may struggle with intricate shapes or highly abrasive materials.

- Operator Skill Requirement: Properly operating a circular saw requires some skill and experience to ensure accurate, safe cuts. Improper use can lead to accidents or poor cut quality.

- Safety Risks: Despite safety features, circular saws still present inherent risks of blade contact and kickback that require careful operator attention.

3. Pneumatic tube cutting machine

Pneumatic tube cutting machine uses the power of compressed air or gas to drive a cutting mechanism, typically a circular saw blade or shearing tool, through the tube material. The compressed air or gas is supplied to a pneumatic cylinder or piston inside the machine, which then pushes the cutting tool forward to slice through the tube that is securely clamped in place. The cutting action is controlled by regulating the flow of the compressed air or gas, and the machine is designed with safety features to protect the operator. Pneumatic cutting is also a type of cold cutting.

Advantages

- Compact design: Since there is no electric motor, the machine becomes smaller and can be used in tight spaces.

- Versatile Cutting: Can handle a variety of tube materials and sizes by adjusting the cutting mechanism.

- Controlled Cutting: The pneumatic power provides a smooth, gradual cutting force for precise, clean cuts.

- Enhanced Safety: Incorporates safety features like guards and automatic shut-offs to protect the operator.

- Easy Maintenance: Simpler design with fewer electrical components makes it easy to service and maintain.

- Cost-Effective: The pneumatic power source is generally more cost-effective than an electric-powered tube cutter.

- Versatile Cutting: Can handle a wide range of tube materials, sizes, and thicknesses.

- Enhanced Safety: Built-in safety features protect the operator during use.

- Suitable for Hazardous Areas: Safe to use in environments with explosion or fire risks.

Limitations

- Limited Power: May struggle with very thick-walled or hard metal tubes compared to electric models.

- Air/Gas Dependency: Requires a constant supply of compressed air or gas to operate, limiting mobility.

- Slower Cutting Speed: Generally has a lower cutting speed than electric saws, reducing productivity.

- Noise and Vibration: The pneumatic operation can generate more noise and vibration during use.

- Potential Air Leaks: Pneumatic components can be prone to air leaks over time, affecting performance.

- Cutting Depth Limitations: Typically restricted to cutting depths of around 2-3 inches.

- Maintenance Requirements: While simpler, the air system still needs regular upkeep.

4. Magnetic tube cutting machine

Magnetic tube cutting machines are suitable for the cutting and beveling of various seamless steel pipes in factories and enterprises of the petroleum, petrochemical, shipbuilding, power generation, and construction installation industries. This machine has two sets of four permanent magnetic wheels, which automatically travel around the steel pipe for cutting through a drive mechanism. The cutting process can use either an oxygen-acetylene flame or an oxygen-propane flame. It can be used to cut and bevel seamless steel pipes of various specifications with a diameter of 108mm or above.

Advantages

- Low price: The structure of the magnetic pipe cutting machine is not complicated and the manufacturing cost is low.

- Simple and convenient assembly: The magnetic pipe cutting machine has few installation parts, can be quickly installed and used, and can be carried anywhere.

- Large cutting angle: The cutting angle can be flexibly adjusted to cut horizontally, vertically, and upward. Supports bevel cutting.

- Non-Contact Cutting: Cutting is done without any physical tool contact, eliminating the risk of tube damage or deformation. This is especially beneficial for thin-walled or delicate pipes.

Limitations

- Material Limitations: Can only handle ferromagnetic materials like steel, not non-magnetic metals.

- Size Limitations: There are limits to the tube size and thickness that can be effectively clamped.

- High Power Consumption: The electromagnetic clamping requires significant electrical power.

- Potential Interference: The strong magnetic fields may disrupt nearby electronic equipment.

- Maintenance Needs: The electromagnetic components still require periodic servicing.

- Higher Initial Cost: Magnetic tube cutters have a higher upfront investment compared to some other options.

- Cutting Depth Restrictions: Limited to cutting depths of around 2-3 inches typically.

5. Plasma tube cutting machine

Plasma tube cutting machines harness a high-velocity stream of ionized gas, known as plasma, to slice through metals with remarkable speed and precision. It operate by generating a plasma arc that is capable of reaching temperatures up to 40,000 degrees Fahrenheit. This intense heat melts the metal at the cutting site, while a high-speed gas jet ejects the molten metal, creating a precise cutting slot.

Advantages

- Material Versatility: Plasma cutters are adept at cutting through a wide variety of conductive metals, including steel, aluminum, and more.

- Thickness Capability: Plasma cutters can handle metal thicknesses up to 38mm, which is significantly greater than the typical 19mm limit of laser cutters.

- CNC Integration: Utilizing CNC technology, plasma cutters can perform automated, programmable cutting operations that enhance precision and reduce the likelihood of human error.

- Cost-Effectiveness: Plasma cutters generally require lower initial investment and operating costs compared to laser cutters.

- Customization and Efficiency: Plasma machines offer high levels of precision and material optimization, which can lead to reduced labor dependency and improved overall safety.

- Wide Material Compatibility: Unlike laser cutters, plasma machines are not affected by the reflective properties of metals, allowing for a broader range of materials to be cut effectively.

Limitations

- Material Limitations: Effective mainly for conductive materials like steel and aluminum, not non-conductive ones.

- Thickness Limitations: Has restrictions on the maximum tube thickness that can be effectively cut.

- Dross Formation: Molten metal debris can accumulate on the cut surfaces, requiring extra finishing.

- High Energy Consumption: The plasma cutting process requires significant electrical power, increasing operating costs.

- Noise and Fume Issues: Generates high-pitched noise and potentially harmful fumes during operation.

- Sensitivity to Impurities: Performance can be affected by contaminants on the tube surface.

- Surface Finish: The cutting surface may be less smooth, with lower cutting precision and more slag compared to other methods like laser cutting.

- Safety Measures: The operation of plasma cutters generates harmful gases and intense arc light, necessitating stringent safety protocols to protect operators.

- Maintenance: Regular maintenance is required to manage the larger cutting slot and ensure the longevity and effectiveness of the cutting blades.

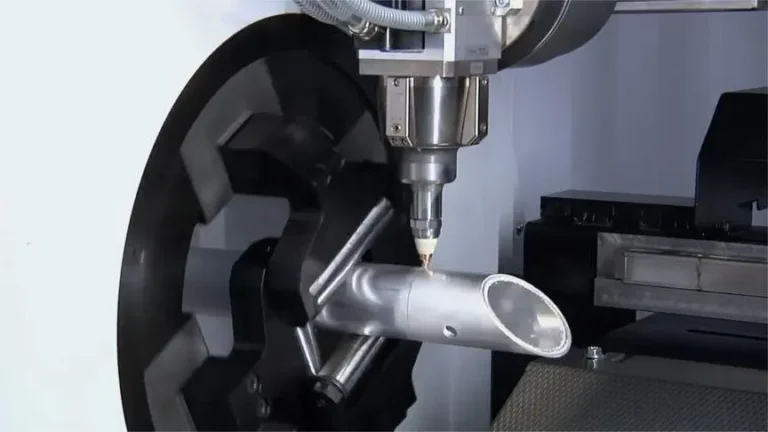

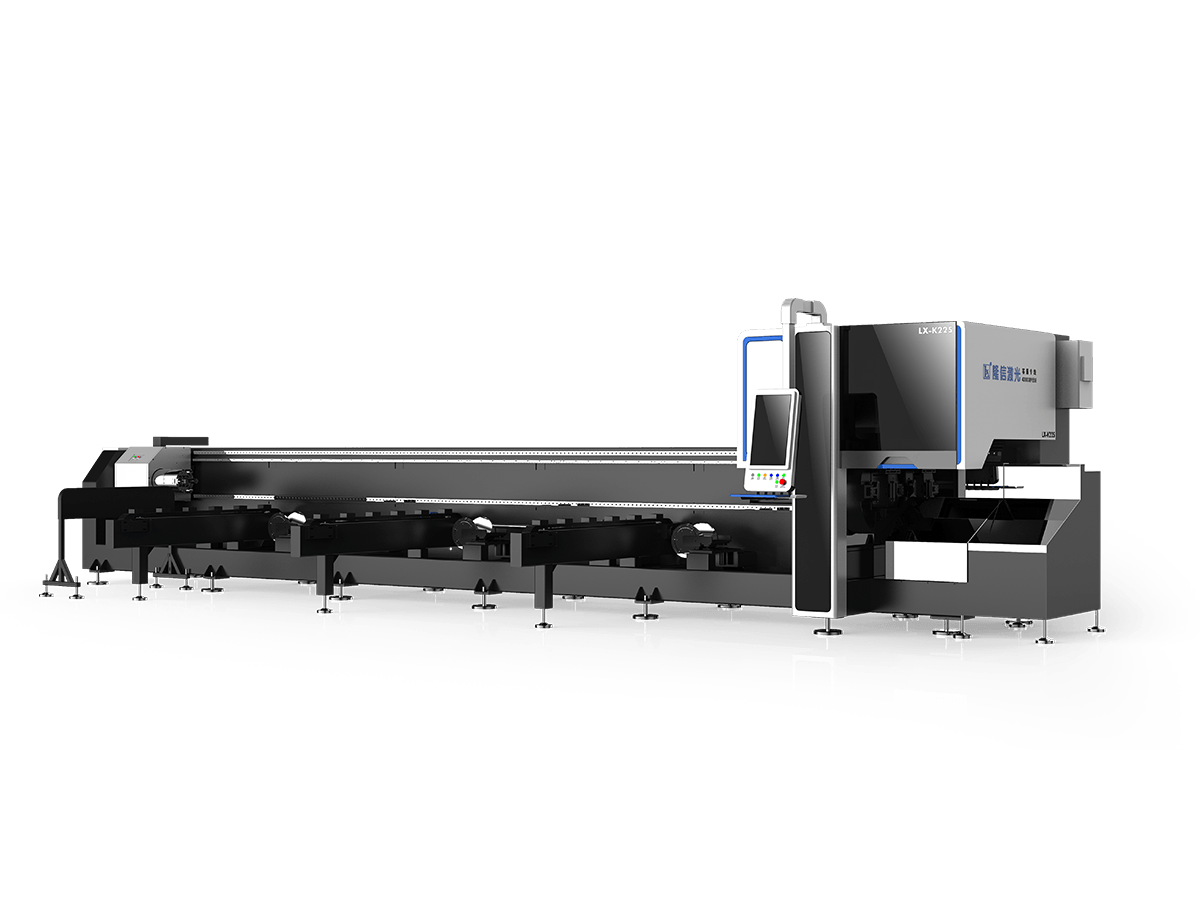

6. Laser tube cutting machine

There is no doubt that the laser pipe cutting machine is currently the fastest growing pipe cutting equipment in the market. Laser pipe cutting machines are able to meet the continuously growing demand in industrial manufacturing, and they have significant advantages in performance, which makes them widely popular in the field of pipe processing.

Advantages

- Higher Precision: Laser cutting achieves much finer, cleaner cut edges than traditional saws or plasma.

- Faster Cutting Speed: Laser cutting is an extremely rapid process, boosting production throughput.

- Non-Contact Cutting: Avoids physical tool contact to prevent damage, especially for thin or delicate tubes.

- Improved Automation: Enables fully automated CNC-programmed operation for greater efficiency.

- Versatility: Can cut a wider range of tube materials, including hard alloys, that traditional methods struggle with.

- Environmental Benefits: Laser cutting is a clean, low-emission process with lower energy use.

Limitations

- Higher Costs: Higher upfront capital investment and ongoing operational expenses compared to traditional tube cutters.

- Thickness Limitations: Best suited for thin to medium-thickness tubes, struggles with very thick-walled tubes.

- Safety Risks: High-power lasers require robust safety measures and specialized operator training.

- Intensive Maintenance: Precise components need regular, meticulous upkeep to maintain cutting quality.

- Material Restrictions: May not be suitable for highly reflective or heat-resistant tube materials.

Table: Comparison of Traditional and Laser Tube Cutting

| Feature | Traditional Cutting Methods | Laser Tube Cutting Machine |

|---|---|---|

| Precision | Lower | High |

| Speed | Moderate | High |

| Material Waste | Higher | Minimal |

| Cost Over Time | Higher maintenance costs | Lower maintenance costs |

| Flexibility | Limited | High |

| Safety | Moderate | Enhanced |

Versatility and Customization

Laser tube cutting machines are not limited to cutting specific types of materials or thicknesses, unlike traditional methods that may require different tools for different materials. These machines excel in customization, capable of handling complex geometries and patterns that would be challenging with other methods. Their ability to cut thin and thick-walled tubes adds to their versatility, making them suitable for a wide range of applications.

Safety and Environmental Considerations

Laser cutting is generally safer and more environmentally friendly compared to traditional methods. The process does not require cutting fluids or lubricants, reducing the production of waste and potential hazards. This aspect of laser tube cutting is particularly important in industries where environmental impact and safety are major concerns.

Economic and Operational Advantages

While the initial setup and investment in laser tube cutting might be higher than traditional methods, the long-term benefits include lower maintenance requirements and reduced need for secondary finishing processes. These factors contribute to a more cost-effective solution over time. Additionally, the integration of automation and software enhances the operational efficiency, further reducing labor costs and improving output quality.

Laser tube cutting machines continue to evolve, integrating cutting-edge technology to meet the growing demands of modern manufacturing. Their ability to deliver precise, efficient, and versatile cutting solutions makes them an indispensable tool in the industrial sector.

7. Comparative Assessment

In the realm of industrial pipe cutting, selecting the right machine hinges on understanding the distinct capabilities and limitations of various cutting technologies. This comparative assessment delves into the specifics of laser cutters, plasma cutters, and cold cutting machines, providing a clear perspective on their operational differences and suitability for different industrial needs.

Laser Cutters vs. Plasma Cutters

Precision and Material Thickness

Laser cutters are celebrated for their exceptional precision, capable of achieving a smaller kerf and leaving minimal residue. This makes them ideal for delicate tasks and precision engraving, where clean cuts are paramount. However, they generally handle materials up to 19mm thick, although more potent models can manage thicker substrates.

Conversely, plasma cutters offer greater versatility in material thickness, efficiently cutting through materials up to 38mm thick. This capability makes plasma cutters suitable for a broader range of industrial applications where material thickness varies.

Cost Considerations

From a financial perspective, plasma cutters typically require a lower initial investment and are less expensive to operate. This cost-effectiveness makes plasma cutters an attractive option for businesses looking to minimize upfront costs.

Safety and Environmental Impact

Both cutting technologies demand strict safety measures due to the production of fumes and other hazardous byproducts. Plasma cutting, in particular, generates fumes, sparks, and radiation, necessitating robust ventilation systems and protective gear to safeguard operator health. Similarly, laser cutters produce intense heat and potentially harmful laser emissions, emphasizing the need for proper safety equipment and training.

Cold Cutting Machines: Safety and Portability

Cold cutting machines, employing a technique that avoids heat and sparks, are particularly advantageous in hazardous environments like hydrocarbon processing. These machines are not only safer but also more economical, reducing the need for complex safety measures and expensive equipment.

Portability and Durability

Cold cutters are designed to be portable, durable, lightweight, and compact, making them ideal for on-site jobs where equipment mobility is crucial. This portability does not compromise their performance, as they still offer the precision needed for effective pipe cutting.

Choosing the Right Machine

When selecting a pipe cutting machine, several factors should be considered:

- Material Type and Thickness: Assess whether the material to be cut and its thickness align with the capabilities of the laser cutter, plasma cutter, or cold cutter.

- Precision Needs: Determine the level of precision required for the task. For high-precision cuts, a laser cutter may be necessary, whereas plasma cutters are suitable for less demanding precision tasks.

- Operational Environment: Consider the operational environment. In hazardous areas, cold cutters offer a safer alternative.

- Cost-Effectiveness: Evaluate the budget constraints and the total cost of ownership, including maintenance and operational costs. Plasma cutters might be preferable for budget-conscious operations.

Table: Comparative Overview of Cutting Technologies

| Feature | Laser Cutter | Plasma Cutter | Cold Cutter |

|---|---|---|---|

| Precision | High | Moderate | Moderate |

| Material Thickness | Up to 19mm (higher with powerful models) | Up to 38mm | Varies |

| Cost | Higher initial and operational costs | Lower initial and operational costs | Economical |

| Safety | High heat, risk of eye damage | Fumes, sparks, radiation | Safer, no sparks or heat |

| Suitability | Delicate tasks, engraving | Versatile material thickness | Hazardous environments |

This comparative analysis underscores the importance of matching the cutting machine’s capabilities with the specific requirements of the industrial tasks at hand, ensuring both efficiency and safety in operations.

8. Conclusion

Through the exploration of various pipe cutting machines, it is evident that the choice of an appropriate cutting tool hinges on a balance of precision, material thickness, operational environment, and cost considerations. Each machine, from the versatile pneumatic and magnetic tube cutters to the advanced laser and plasma models, offers unique advantages tailored to specific industrial applications. This guide has delineated these differences, providing a comparative insight to assist in the decision-making process, ensuring that the most suitable cutting solution is selected for efficient, safe, and cost-effective operations.