What is a Channel Section?

A channel section, also called a channel bar or C-channel, is a steel profile that resembles the letter “C” in its cross-section. It is widely used in construction, manufacturing, and transportation industries due to its versatility and strength-to-weight ratio.

Channel sections come in various sizes and materials to meet different application needs. They can range from small, lightweight profiles to larger, heavy-duty versions. Materials include mild steel, stainless steel, and aluminum.

The unique shape of channel sections allows them to be used in a variety of applications, such as:

- Structural framing for buildings and machinery

- Reinforcement for concrete structures

- Fabrication of racking systems and shelving units

- Manufacturing of agricultural equipment and trailers

- Automotive and transportation industry components

With their widespread use across multiple sectors, the ability to efficiently and accurately cut channel sections is crucial for many manufacturing processes.

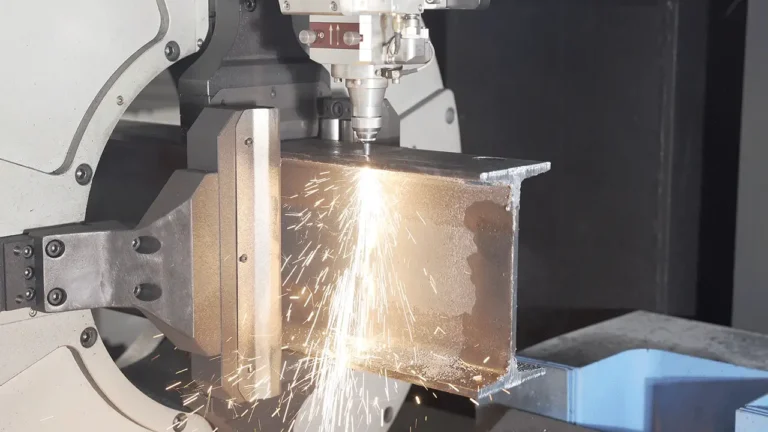

Can a tube laser machine cut channel sections?

Yes, a tube laser machine can effectively cut channel sections. These machines are designed to handle a wide range of materials, including structural steel profiles like channel sections. Tube laser machines use laser technology to cut through channel sections with high accuracy and minimal material deformation.

The tube laser cutting process involves focusing a high-energy laser beam onto the material’s surface, melting and vaporizing a small portion of the material along the desired cut path. This is done using a specialized nozzle or cutting head mounted on a computer-controlled gantry system. The gantry system allows for precise positioning and movement of the cutting head, enabling intricate cuts and complex shapes.

One advantage of using a tube laser machine for cutting channel sections is its ability to handle various thicknesses and materials. Depending on the laser system’s power and specifications, tube laser machines can cut through channel sections with thicknesses ranging from millimeters to inches.

Advantages of using a tube laser machine for cutting channel sections

Using a tube laser machine for cutting channel sections offers several advantages over traditional cutting methods:

- Precision and Accuracy: Laser cutting technology ensures exceptional precision and accuracy, allowing for tight tolerances and intricate cut patterns. This is particularly important when working with channel sections, where precise dimensions and angles are crucial for proper fit and assembly.

- Minimal Deformation: Unlike mechanical cutting methods, laser cutting minimizes material deformation and distortion. This is especially beneficial for channel sections, as their unique shape can be susceptible to warping or deformation during cutting processes.

- Clean Cuts: Laser cutting produces clean, burr-free cuts with minimal heat-affected zones (HAZ). This reduces the need for additional finishing operations and ensures a high-quality end product.

- Versatility: Tube laser machines can handle a wide range of materials, including mild steel, stainless steel, and aluminum, making them suitable for cutting channel sections made from various alloys.

- Automation and Efficiency: Tube laser machines are highly automated, allowing for efficient and consistent production. They can be integrated into larger manufacturing systems, streamlining the cutting process and reducing labor costs.

- Complex Geometries: The computer-controlled nature of tube laser machines allows for cutting complex geometries and shapes, enabling greater design flexibility when working with channel sections.

- Reduced Material Waste: Laser cutting is a highly efficient process, minimizing material waste and maximizing material utilization, resulting in cost savings and improved sustainability.

Limitations or challenges of using a tube laser machine for cutting channel sections

While tube laser machines offer numerous advantages for cutting channel sections, there are also some limitations and challenges to consider:

- Initial Investment: Tube laser machines can be a significant capital investment, especially for larger or more advanced systems. This initial cost may be a barrier for smaller businesses or those with limited budgets.

- Material Thickness Limitations: While tube laser machines can handle a wide range of thicknesses, there are practical limitations based on the laser power and optics. Extremely thick channel sections may require alternative cutting methods or multiple passes, which can impact efficiency and productivity.

- Heat-Sensitive Materials: Certain materials, such as aluminum alloys or thin-walled channel sections, may be more susceptible to heat-related issues during laser cutting. Proper parameter settings and cooling mechanisms are crucial to mitigate these challenges.

- Reflective Surfaces: Highly reflective materials, like polished stainless steel, can pose challenges for laser cutting due to the potential for beam reflection and inconsistent energy absorption. Surface preparation or specialized laser parameters may be necessary.

- Operator Training: Tube laser machines require skilled operators who are trained in programming, setup, and maintenance. Proper training and experience are essential for optimizing the cutting process and ensuring consistent results.

- Maintenance and Operating Costs: Tube laser machines require regular maintenance, consumable replacements (e.g., lenses, nozzles), and operational costs (e.g., electricity, gas). These ongoing expenses should be factored into the overall cost of ownership.

Comparison to Other Cutting Methods

While tube laser machines offer numerous advantages for cutting channel sections, it is essential to consider alternative cutting methods and their respective strengths and limitations:

- Plasma Cutting: Plasma cutting is a cost-effective alternative for cutting thicker channel sections, particularly those made of mild steel. However, it may produce rougher cut edges and higher heat-affected zones compared to laser cutting.

- Oxy-Fuel Cutting: Oxy-fuel cutting is a traditional method suitable for cutting thicker channel sections, but it can be slower, less precise, and prone to more material deformation compared to laser cutting.

- Waterjet Cutting: Waterjet cutting is a cold-cutting process that minimizes heat-related deformation and can handle a wide range of materials, including channel sections. However, it may be slower and less precise than laser cutting for certain applications.

- Bandsaw Cutting: Bandsaws are commonly used for cutting channel sections, particularly in smaller workshops or for lower production volumes. While cost-effective, bandsaw cutting can be less precise, produce rougher edges, and may be limited in terms of cut complexity.

For a comparison of different cutting methods for tube materials, you can refer to this article “Exploring the Different Types of Tube Cutting Machines“.

Conclusion

In conclusion, tube laser machines are highly capable and versatile cutting systems that can effectively cut channel sections with precision, accuracy, and minimal material deformation. By leveraging the power of laser technology, these machines offer numerous advantages, including clean cuts, intricate geometries, and efficient automation.

If you’re looking to streamline your channel section cutting processes and achieve superior results, consider investing in a state-of-the-art tube laser machine. At our company, we offer a wide range of tube laser cutting systems tailored to meet your specific requirements.

Our experienced team will work closely with you to understand your needs and provide a comprehensive solution, from machine selection to installation, training, and ongoing support. Contact us today to learn more about how our tube laser machines can revolutionize your channel section cutting operations and drive your business to new heights.