In the world of modern manufacturing, laser cutting technology has revolutionized the way we process metal tubes. From high precision to incredible efficiency, laser cutting offers a multitude of advantages over traditional methods. Here, we explore five common laser cutting processes used for metal tubes, detailing their types, applications, and benefits.

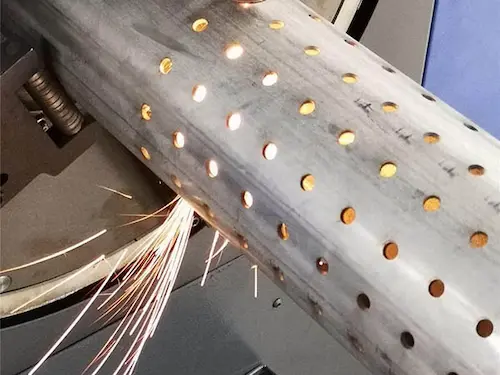

1. Laser Drilling for Tubes

Laser drilling is an advanced material processing technology that uses high power density laser beams to precisely create holes in materials. There are several types of laser drilling:

- Single Pulse Drilling: Ideal for thin materials, this method uses a single high-energy pulse to create a hole.

- Percussion Drilling: Involves multiple pulses to gradually remove material.

- Helical Drilling: Suitable for large diameter, deep holes, this method creates a spiral path.

- Trepan Drilling: Starts with an initial hole and then expands the diameter.

Applications:

- Industrial Manufacturing: Micro-hole processing in metals and ceramics.

- Electronics: Drilling micro-holes in PCBs and integrated circuits.

- Medical Devices: Precision drilling for medical catheters.

- Aerospace: Creating holes in composite materials and high-temperature alloys.

- New Energy: Micro-hole processing in lithium battery separators.

Key Advantages:

- Fast Processing Speed: High efficiency.

- Large Depth-to-Diameter Ratio: Excellent for deep holes.

- Material Versatility: Suitable for hard, brittle, and soft materials.

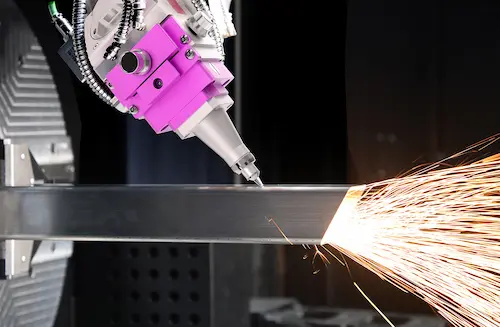

2. Tube Laser Cutting

Laser cutting tubes is an advanced technique with various process types and significant benefits. Here’s a closer look at the main types:

- CO2 Laser Cutting: Suitable for non-metal and some metal tubes.

- Fiber Laser Cutting: Ideal for all types of metal tubes, especially reflective materials.

- 3D Tube Laser Cutting: Capable of cutting complex shapes and angles.

- Rotary Axis Cutting: The tube rotates while the laser is fixed, perfect for circumferential cuts.

- Flying Optics Cutting: The laser head moves while the workpiece is fixed, suitable for large or heavy tubes.

Advantages:

- High Precision: Cutting accuracy up to ±0.05mm.

- Excellent Cut Quality: Smooth, burr-free edges with minimal heat-affected zones.

- High Speed: 3-5 times faster than traditional methods.

- Flexibility: Quick program changes to meet diverse product needs.

- Non-Contact Processing: Reduces material deformation and contamination.

- Multi-Functionality: Capable of cutting, drilling, and slotting.

- Eco-Friendly: High energy efficiency without the need for cooling liquids.

Applications:

- Automotive: Exhaust systems, fuel lines, chassis components.

- Aerospace: Lightweight structural components, engine parts.

- Construction: Steel structures, decorative tubes.

- Furniture: Metal frames for chairs and tables.

- Medical Devices: Precision instruments and implants.

- Electronics: Heat sinks, enclosures.

- Energy Equipment: Battery housings, liquid cooling plates.

- Fitness Equipment: Tubular structures.

- Advertising Signage: Metal letters and logos.

3. Tube Bevel Cutting

Bevel cutting with lasers is a sophisticated metal processing technique that allows for the cutting of inclined or angled surfaces. This method can achieve bevel angles from 1° to 45°, producing complex shapes such as V, Y, X, and K.

Applications:

- Pre-Welding Preparation: Enhances welding strength and quality.

- Steel Structures: Bridges, buildings, beams.

- Pipeline Manufacturing: Precision fitting of pipe joints.

- Automotive: Body panels, suspension parts.

- Shipbuilding: Cutting hull plates and joint structures.

- Aerospace: Ensuring structural integrity and reliability of aircraft components.

Key Advantages:

- High Efficiency: Faster than traditional mechanical methods, completing multiple steps in one go.

- High Precision: Accurate bevel shapes and angles, with cutting precision up to ±0.05mm.

- Excellent Cut Quality: Smooth, burr-free edges with minimal heat-affected zones.

- Flexibility: Quick program adjustments for diverse product requirements.

- Wide Material Compatibility: Works with various metals including stainless steel, aluminum, and titanium alloys.

- Reduced Post-Processing: Directly cuts complex bevel shapes, reducing additional grinding and processing steps.

- Enhanced Welding Quality: Precise bevel cutting improves the strength and quality of weld joints.

- Eco-Friendly: High energy efficiency without the need for cooling liquids.

4. Tube Laser Cutting and Tapping

In the world of industrial manufacturing, efficiency and precision are key. That’s why the new integrated laser tube cutting and tapping machine is a game-changer. This advanced equipment combines cutting and tapping processes into one seamless operation, significantly boosting productivity and automation.

How It Works?

The machine features a sturdy frame, with Z-axis and Y-axis slides and their respective drive mechanisms. At its core is the drilling and tapping assembly, which includes a motor, a gearbox, multiple chuck mounts, drill chucks, and a drill drive mechanism.

Here’s a simple breakdown:

- Motor and Gearbox: The motor connects to the input shaft of the gearbox. The gearbox then drives multiple output shafts.

- Chucks and Drill Drive: Drill chucks are mounted on these output shafts, allowing the machine to perform both drilling and tapping operations simultaneously.

Key Advantages:

- Fast Processing: Higher efficiency than traditional mechanical tapping.

- Non-Contact Processing: Reduces tool wear and extends tool life.

- Wide Applicability: Suitable for hard-to-machine materials like hard alloys.

- High Precision: Ideal for processing small, precise threads.

- Flexibility: Programmable for quick changes between different thread specifications.

Applications:

- Aerospace: Threading lightweight structural components.

- Medical Devices: Precision threading of small parts.

- Automotive: Threading complex engine components.

- Electronics: Threading PCBs and precision connectors.

Comparison with Traditional Tapping:

- Eco-Friendly: No cutting fluid required.

- Minimal Heat Affected Zone: Reduces risk of micro-cracks.

- Versatile: Capable of threading deep and blind holes.

- Clean Process: No chips generated, reducing cleanup.

5. Tube Laser Engraving

Laser engraving is an effective method for marking and processing metal tubes across various industries. Here are some key points about tube laser engraving:

Technology:

- Laser cutting machines use laser technology to cut, engrave, and process tubes.

- Common types include CO2 lasers and fiber lasers, with fiber lasers being more suitable for metal tubes.

- 3D tube laser cutting allows for complex shapes and angles on tubes.

Applications:

- Widely used in automotive, aerospace, furniture manufacturing, medical devices, and construction.

- Capable of cutting, engraving, marking, and creating complex shapes on tubes.

- Useful for traceability marking, product identification, and decorative purposes.

Advantages:

- High Precision: Accuracy up to ±0.05mm.

- Fast Processing Speed: Faster than traditional methods.

- Versatility: Capable of cutting complex shapes and patterns.

- Non-Contact Process: Minimizes material deformation.

- Material Flexibility: Works with different materials and tube shapes.

Materials:

- Processes a variety of metals including stainless steel, carbon steel, aluminum, and alloys.

- Depending on the laser type, suitable for certain non-metal materials as well.

Marking Methods:

- Direct Laser Engraving

- Laser Annealing: Changes color without removing material.

- Laser Ablation: Removes surface layers.

Considerations:

- Choosing between CO2 and fiber lasers depends on the material being processed.

- Rotary attachments are often used for 360-degree processing of cylindrical objects.

- Software plays a crucial role in programming complex cuts and designs.

Laser engraving and cutting for tubes offer significant advantages in speed, precision, and versatility compared to traditional methods. This technology has become essential in many manufacturing processes, enabling more efficient production and offering greater design possibilities.

In summary, laser cutting technology for metal tubes has become indispensable in modern manufacturing. Whether it’s drilling, cutting, beveling, tapping, or engraving, each process offers unique advantages that cater to diverse industrial needs. As laser technology continues to advance, its application scope and performance will only expand, driving innovation and efficiency in production.